In the competitive landscape of the global souvenir supply chain, the difference between a high-margin success story and a logistical nightmare often comes down to a single decision: your choice of a manufacturing partnership.

For a tourism souvenir importer, wholesaler, or brand retailer, the stakes have never been higher. As we move through 2026, “surface-level” vetting—simply checking an Alibaba Gold Supplier badge or a few factory photos—is no longer enough to protect your profit optimization. The market is flooded with trading companies posing as factories and workshops that lack the technical infrastructure to handle complex bulk souvenir orders.

To ensure your private label souvenirs meet global retail standards, you need a rigorous, data-driven framework. This guide provides the Skyscraper-level depth required to move beyond basic due diligence. We’ve synthesized competitor data and enhanced it with deep industry insights to bring you the definitive 7-point checklist for vetting a China souvenir factory.

1. Legal Legitimacy and Export-Specific Business Scope

The first gate is legal. However, many importers fail because they look for a business license but don’t know how to read the Business Scope.

A legitimate China souvenir factory must have a business scope that explicitly includes “Manufacturing” and “Export”. If the scope only lists “Wholesale” or “Consulting,” you are likely dealing with a middleman.

- Unified Social Credit Code: Verify the 18-digit code on the National Enterprise Credit Information Publicity System. This ensures the company is not on the “Abnormal Operation List.”

- Export License Ownership: Does the factory hold its own export license, or do they use a third-party agent? Direct export capability often translates to better landed cost analysis because the factory can claim the Export Tax Rebate, passing those savings on to you in your wholesale pricing.

2. Technical Specialization & Material Lineage

A common mistake in souvenir product development is choosing a “Generalist” factory. A factory that claims to make silicone wristbands, resin figurines, and metal keychains all in-house is usually a trading company.

True profit optimization comes from Material Specialization.

- The Resin Specialist: A high-end resin souvenir manufacturer will have dedicated curing rooms, temperature-controlled painting booths, and a specific “material lineage” in polyresin and stone-powder mixes.

- The Ceramic Expert: Ceramic souvenir production requires kilns and specialized clay-aging facilities.

- The Red Flag: If you are a wholesaler looking for high-detail custom souvenirs, ask for a list of their machinery. A resin factory should own vacuum-casting machines and 3D printers for prototyping. If they can’t show you the floor where the resin is poured, they aren’t the manufacturer.

3. The 3rd Generation Sampling Protocol: From STL to Physical PPS

In 2026, a “good sample” is not enough. You need to vet the process of sampling. A professional manufacturing partnership should offer what we call the 3rd Generation Sampling Protocol.

- 3D Rendering & STL Files: The factory should be able to take your 2D sketches and provide a 3D digital model for approval before any physical mold is made.

- 3D Printed Prototype: Instead of jumping to expensive steel or silicone molds, a vet-worthy factory will provide a 3D-printed gray model to check proportions.

- The Master Pre-Production Sample (PPS): This must be the exact material and paint finish as the final production.

Ask the factory: “Do you keep a ‘Gold Sample’ in your office for every client?” A reliable China souvenir factory will keep a duplicate of your approved PPS to use as the bench-mark for souvenir quality control during the bulk run.

4. Precision Quality Assurance (AQL 2.5 / 4.0 Standards)

Don’t just ask if they “do QC.” Demand to see their Quality Management System (QMS) documentation and their adherence to Acceptable Quality Limit (AQL) standards.

For bulk souvenir orders, the industry standard is typically:

- Critical Defects (0%): Safety issues or legal non-compliance.

- Major Defects (2.5%): Functional issues or significant aesthetic flaws (e.g., broken limbs on a figurine).

- Minor Defects (4.0%): Small paint bleeds or tiny air bubbles in resin.

Souvenir-Specific QC Checkpoints:

- Paint Adhesion Test: Do they perform a 3M tape test to ensure the paint doesn’t peel?

- Drop Test: For fragile ceramic souvenir production, do they perform a 1-meter drop test in the final export packaging?

- Weight Consistency: In resin souvenir manufacturer runs, inconsistent weight often indicates air pockets, which lead to breakage during souvenir import logistics.

5. Compliance as a Competitive Edge (FSC, BSCI, and Global Brand Audits)

If you are a brand retailer or a tourism souvenir importer supplying major gift shops (like those at Universal Studios or National Parks), compliance is your “license to play.”

- Social Compliance: Look for BSCI or Sedex (SMETA) audit reports. These prove the factory treats workers ethically, protecting your brand from “sweatshop” scandals.

- Environmental Compliance: For wooden products, an FSC-certified wooden souvenir China supplier is a must. It proves the wood is sustainably sourced, which is a growing requirement in the European and North American markets.

- Brand-Specific Audits: Ask if they have a Disney FAMA (Facility and Merchandise Authorization) or have passed a Universal Studios audit. These are the gold standards of manufacturing capability.

6. Logistical Integrity & Packaging Engineering

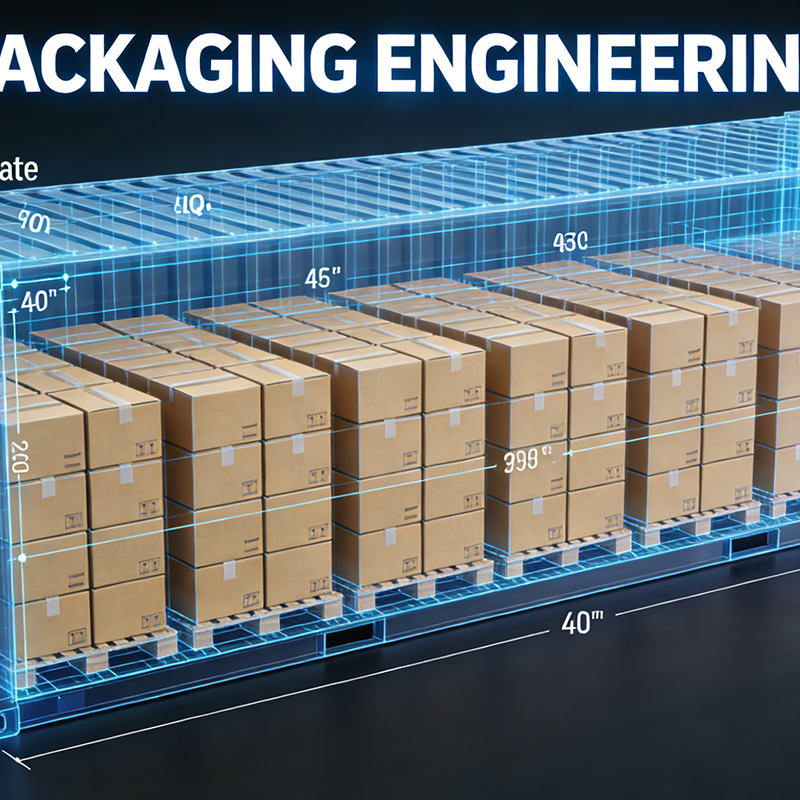

A factory that ignores packaging is a factory that ignores your profit. As discussed in our guide on volumetric weight, shipping air is a margin killer.

A vet-worthy manufacturing partnership provides:

- Packaging Engineering: They should design inner boxes and master cartons that achieve at least a 95% container fill rate.

- Landed Cost Transparency: They should be able to give you accurate CBM (Cubic Meter) and weight estimates during the quoting stage, not after the goods are finished.

- Palletization Knowledge: Do they understand the specific pallet requirements for your region (e.g., Euro-pallets vs. US-standard pallets)? This prevents costly “re-palletizing” fees at the destination port.

7. Communication Proactivity & The “Consultant” Mindset

Finally, vet the people. A “Yes-Man” factory is dangerous. If you send a design that is technically impossible to manufacture in resin without high breakage, a low-quality factory will say “No problem” and then send you a container of broken goods.

A high-value China souvenir factory acts as a Product Development Consultant.

- They Suggest Improvements: “If we thicken this joint by 2mm, the breakage risk drops by 15%.”

- They Are Proactive About Holidays: As we noted in our CNY/Golden Week lead time guide, a professional partner will warn you 2 months in advance about factory closures.

- English Proficiency: In 2026, AI helps, but your primary account manager must understand the nuance of “matte finish vs. satin finish” to avoid expensive private label souvenirs errors.

The Data: Premium Factory vs. Low-End Workshop

To help your landed cost analysis, here is a comparison of what you get when you choose a vetted manufacturing partnership like Craftmgf.com versus a low-end, non-vetted workshop.

| Metric | Low-End Workshop (Alibaba Tier 3) | Premium Vetted Factory (Craftmgf) | Impact on Profit Optimization |

| Sampling Success Rate | 40% (Multiple rounds needed) | 90% (Precision 3D modeling) | Saves 2-4 weeks in lead time. |

| Material Quality | Recycled/Mixed Resins | Virgin Resin + Stone Powder | Drastically lower breakage rates. |

| QC Methodology | “Visual Check” by workers | AQL 2.5 / 4.0 (Independent Team) | Prevents 5-10% in product returns. |

| Compliance | None | FSC, BSCI, Disney FAMA | Essential for brand retailers. |

| Communication | Reactive (Wait for your call) | Proactive (Consultative approach) | Reduces supply chain anxiety. |

| Landed Cost Accuracy | Guesswork | Data-driven packaging engineering | Reduces freight costs by up to 15%. |

Conclusion: Securing Your Manufacturing Partnership

Vetting a Chinese custom souvenir manufacturer is not a one-time event; it is an ongoing process of building trust through data and transparency. By following this 7-point checklist, you move from being a “buyer” to a “strategic partner.”

For wholesalers and tourism souvenir importers, your choice of factory is the foundation of your business. Don’t build your brand on the shifting sands of unverified suppliers. Demand the standards, the compliance, and the technical expertise that your bulk souvenir orders deserve.

Are you ready to elevate your sourcing strategy? At Craftmgf.com, we specialize in the high-detail, compliant manufacturing that global brands demand. Contact us today for a factory audit profile and a comprehensive consultation on your next custom souvenir project.

- Resin vs. Ceramic: A Data-Driven B2B Comparison for High-Volume Souvenir Orders - February 4, 2026

- AQL 2.5 vs. 4.0: Defining Acceptable Defect Thresholds for Mass-Produced Tourist Magnets - January 28, 2026

- The Importer’s Guide to Total Landed Cost (TLC): Calculating the Real Price of Resin Souvenirs from Quanzhou - January 21, 2026