Souvenirs are more than just trinkets; they’re cultural ambassadors, fostering connection and a tangible reminder of cherished travel experiences. For artisans and businesses in the souvenir craft export industry, these handcrafted treasures represent a thriving economic force. But in a global marketplace, ensuring consistent quality across exported souvenir crafts is paramount.

Imagine a customer receiving a chipped figurine or a poorly woven textile – not only does it disappoint them, but it tarnishes your brand reputation and risks a domino effect of negative reviews. Fortunately, by establishing effective quality assurance (QA) procedures, you can build trust with customers, safeguard your reputation, and unlock the competitive advantage of exceptional souvenir crafts.

The Power of Souvenirs: More Than Just Trinkets

Think back to your travels. Perhaps you have a hand-painted ceramic plate from Italy adorning your kitchen wall, or a vibrantly woven scarf from Thailand draped across your favorite armchair. Souvenirs are more than just decorative items; they’re conversation starters, evoking memories of adventures and immersing us in the cultural tapestry of a place. They act as bridges between cultures, fostering a sense of connection and reminding us of the beauty and diversity of our world.

The souvenir economy plays a vital role in supporting local artisans and communities. Tourists seeking authentic keepsakes directly contribute to the livelihoods of skilled craftspeople, preserving traditional techniques and fostering cultural appreciation. For souvenir craft export businesses, delivering high-quality products ensures the continued success of this mutually beneficial exchange.

Why Quality Assurance Matters in Souvenir Craft Exports

In today’s competitive market, customer satisfaction reigns supreme. A single negative experience with a souvenir can quickly spread through online reviews, jeopardizing your reputation and impacting future sales. Building trust with customers requires a commitment to consistent quality. Each souvenir you export represents your brand – a poorly crafted item reflects poorly on your entire business.

Beyond customer satisfaction, effective QA procedures help avoid costly issues down the line. Imagine a shipment of souvenirs arriving at their destination with broken pieces or faulty construction. The hassle and expense of returns or replacements can be significant. Implementing proactive quality control measures at every stage of the production process minimizes these risks and ensures your business operates smoothly.

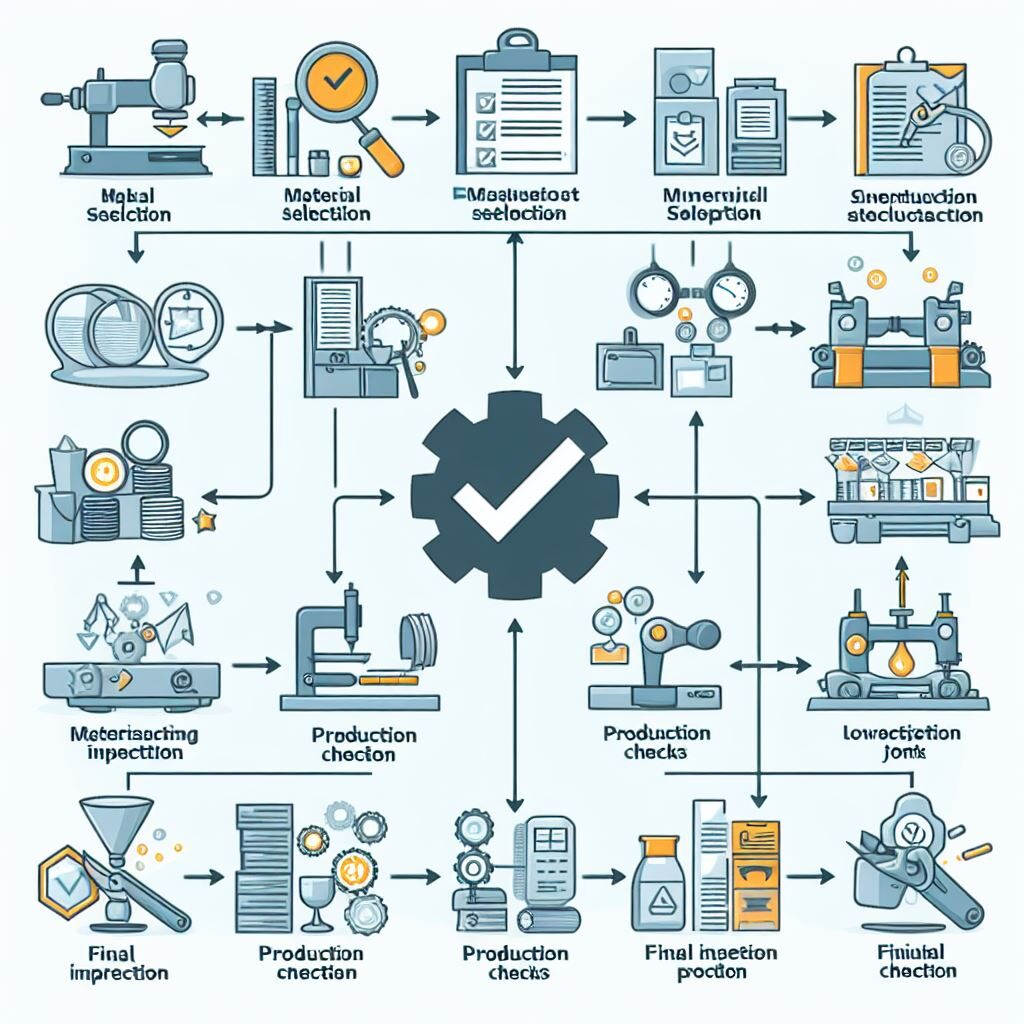

Implementing Effective Quality Assurance Procedures

Building a robust QA framework is a cornerstone of success in the souvenir craft export industry. Here’s how to get started:

- Defining Quality Standards: Set clear benchmarks for the materials, craftsmanship, and overall finish of your souvenir products. This includes establishing guidelines for material durability, color consistency, and adherence to traditional design elements.

- Raw Material Selection: The foundation of a quality souvenir begins with high-quality materials. Develop a sourcing strategy that prioritizes ethically sourced, durable materials that are safe for use. Regular inspections of raw materials can identify any potential issues before they impact the final product.

- Production Process Control: Implement quality control checkpoints throughout the production process. Train artisans to identify and address any inconsistencies in workmanship. This could involve inspecting stitching on textiles, checking for paint blemishes on ceramics, or ensuring proper assembly of wooden crafts.

- Final Inspection: Before packing and shipping, conduct a thorough final inspection of each souvenir. This is the last line of defense to catch any imperfections that may have slipped through earlier checks. Utilize checklists to ensure every aspect of the souvenir meets your quality standards.

- Documentation and Record Keeping: Maintain meticulous records of your QA procedures. This includes documenting the types of quality checks performed, the personnel involved, and any corrective actions taken. Detailed records demonstrate transparency and accountability within your supply chain.

Addressing Common Quality Concerns in Souvenir Crafts

Even with robust QA procedures, specific quality concerns can arise in souvenir crafts. Here’s how to address some common issues:

- Material Defects: Ensure the materials used in your souvenirs are durable and safe for their intended purpose. For example, paints and dyes should be non-toxic, and textiles should be colorfast to prevent fading. Regular testing of materials can identify any potential problems.

- Workmanship Inconsistencies: Maintaining consistent craftsmanship is crucial for high-quality souvenirs. Invest in training programs for artisans to ensure they possess the necessary skills and techniques to produce flawless work. Providing clear instructions and production guidelines can also minimize inconsistencies.

- Inaccurate Depictions: Souvenirs that misrepresent cultural elements can be disrespectful and disappointing for customers. Work closely with artisans to ensure their designs accurately reflect traditional styles and motifs. Researching cultural significance can also help avoid unintentional offense.

Building a Culture of Quality: Beyond Procedures

While procedures are essential, building a culture of quality goes beyond simply having a checklist. Here are some additional strategies:

- Empowering Artisans: Foster a sense of ownership and pride among the artisans who create your souvenirs. Provide them with opportunities to offer feedback on the QA process and suggest improvements. This collaborative approach can lead to a more engaged workforce and higher quality products.

- Continuous Improvement: Commit to continuous improvement in your QA practices. Regularly review your procedures, analyze customer feedback, and identify areas for enhancement. Embrace innovation and adapt your QA measures to stay ahead of the curve.

The additional investment in building a culture of quality pays dividends in the long run. Empowered artisans take greater pride in their work, leading to a noticeable improvement in craftsmanship. A commitment to continuous improvement ensures your QA procedures remain effective and adaptable in an ever-evolving market.

The Competitive Advantage of Quality Souvenirs

By prioritizing quality assurance, you’re not just safeguarding your reputation; you’re unlocking a significant competitive advantage. Here’s how:

- Premium Pricing: Exceptional quality commands a premium price. Customers are willing to pay more for well-made, authentic souvenirs that will last a lifetime. Effective QA allows you to confidently position your products within a higher price range, reflecting the superior craftsmanship and materials used.

- Customer Loyalty: When customers consistently receive high-quality souvenirs, they become loyal brand advocates. Positive experiences translate into repeat purchases and glowing reviews, attracting new customers and establishing your brand as a trusted source for exceptional souvenirs.

- Positive Word-of-Mouth: In today’s digital age, word-of-mouth marketing holds immense power. Satisfied customers are more likely to share their positive experiences online and recommend your souvenirs to friends and family. By prioritizing quality, you cultivate a legion of brand ambassadors who organically promote your business.

Conclusion: Safeguarding Your Souvenir Craft Export Business

In the dynamic world of souvenir craft exports, quality assurance is not an option; it’s a necessity. By establishing effective QA procedures, you build trust with customers, safeguard your brand reputation, and unlock the competitive advantage of exceptional craftsmanship. Remember, every souvenir you export represents your brand and its commitment to cultural authenticity and artistic excellence. Invest in quality, and watch your souvenir craft export business flourish.

FAQs

1. How can I ensure my QA procedures are effective?

Regularly review your procedures, analyze customer feedback, and conduct internal audits to identify areas for improvement. Embrace a culture of continuous improvement and adapt your QA measures to stay ahead of the curve.

2. What are some additional benefits of maintaining high-quality standards?

Strong QA procedures can streamline your production process, minimize waste, and improve overall efficiency. Additionally, high-quality souvenirs are less likely to incur damage during shipping, reducing replacement costs and customer dissatisfaction.

3. How can I communicate my commitment to quality to customers?

Highlight your QA procedures on your website and marketing materials. Showcase the skills and expertise of your artisans. Customer testimonials praising the quality of your souvenirs can also build trust and credibility.

4. What are some resources available to help me improve my QA procedures?

Industry associations and government agencies often offer resources and training programs on quality control practices. Consider attending trade shows and workshops to stay updated on the latest advancements in QA for souvenir crafts.

5. How can technology play a role in my QA processes?

Technology can be a valuable asset in your QA toolbox. Digital inspection tools can help identify inconsistencies in craftsmanship. Cloud-based document management systems can streamline record keeping and ensure transparency throughout your supply chain.

By implementing these strategies and remaining committed to quality, you can establish your souvenir craft export business as a leader in the industry, renowned for its dedication to cultural preservation and exceptional craftsmanship.