Success Stories: How Leading Brands Built Their Souvenir Empires with Strategic Sourcing

Every tourism souvenir importer, wholesaler, and brand retailer dreams of building a thriving business, an “empire” if you will, in the competitive global souvenir market. But what truly separates those who merely survive from those who genuinely flourish, consistently attracting customers and expanding their reach? Often, it boils down to one critical factor: strategic sourcing. It’s not just about finding a manufacturer; it’s about forging a profound manufacturing partnership that elevates your entire operation, especially when dealing with the intricacies and scale of bulk souvenir orders.

Today, we’re pulling back the curtain on real-world examples – meticulously inspired by countless success stories we’ve witnessed and facilitated within the industry – to show you precisely how leading brands leveraged smart, insightful sourcing to transform their initial vision into formidable souvenir empires. These aren’t just feel-good anecdotes; they’re meticulously crafted blueprints for sustainable profit optimization, accelerated brand growth, and resilient global souvenir supply chain management. If you’re earnestly looking to elevate your wholesale souvenirs business and secure large quantity souvenir production that truly delivers consistent quality and value, this article is your indispensable guide.

The Foundation of an Empire: Understanding Strategic Sourcing

Before we delve into these inspiring and instructive tales of success, let’s establish a clear understanding of what strategic sourcing truly means in the dynamic context of tourism souvenirs. It’s a concept far more sophisticated and impactful than simply comparing unit prices from a handful of souvenir suppliers China. It’s a holistic, proactive, and foresightful approach to procurement that meticulously considers every single facet of your overarching business goals, aligning supplier capabilities with your long-term vision.

Beyond Price: The Indispensable Pillars of Strategic Sourcing

While cost-effectiveness is, without a doubt, an undeniably important consideration for any business, strategic sourcing goes profoundly deeper. For bulk souvenir orders, where volume and consistency are paramount, it encompasses a comprehensive set of non-negotiable pillars:

- Unwavering Quality Consistency: This is the bedrock. It involves ensuring that every single customized souvenir or standard item you receive consistently meets your precise specifications, color accuracy, and finishing standards. This commitment to uniform excellence is absolutely critical for maintaining your brand’s hard-earned reputation, minimizing costly customer returns, and reducing internal rework. Achieving this relies fundamentally on the implementation of robust, end-to-end souvenir quality control processes at the factory level, from raw material inspection (IQC) to in-process checks (IPQC) and rigorous pre-shipment inspections (PSI).

- Reliability & Predictable Timeliness: In the fast-paced world of tourism, missing deadlines for large scale manufacturing can lead to significant lost sales opportunities, depleted inventory, and damaged relationships with your retail partners. Strategic sourcing prioritizes working with a souvenir supplier China that consistently delivers on time, maintains predictable lead times, and can reliably manage fluctuating demand, especially crucial for seasonal travel retail souvenirs and special events.

- Innovation & Bespoke Customization Capabilities: To truly stand out in a crowded market, you need products that speak to your brand’s unique identity. A strategic manufacturing partnership means collaborating with a factory capable of genuine souvenir product development, offering fresh design concepts, utilizing innovative materials, and delivering unique private label souvenirs that resonate deeply with your target audience and effectively differentiate you from competitors. This includes flexibility in design and material choices, like sophisticated options from a resin souvenir manufacturer or intricate designs from a ceramic souvenir production specialist.

- Ethical & Sustainable Practices (ESG Focus): Modern consumers, particularly the eco-conscious segment, are increasingly scrutinizing the origins and production methods of the products they buy. Aligning your brand with responsible values by ensuring ethical sourcing (fair labor, safe conditions) and adopting green souvenir manufacturing practices (recycled materials, reduced waste, lower carbon footprint) not only enhances your brand image but also critically future-proofs your business against evolving consumer preferences and stricter international compliance regulations.

- Transparent & Proactive Communication: The foundation of any strong manufacturing partnership is open, honest, and proactive communication. This involves clear dialogue, timely updates, transparent reporting on production status, and a mutual commitment to resolving challenges together. Effective communication minimizes misunderstandings, reduces costly errors, and builds the trust essential for managing a complex global souvenir supply chain for bulk souvenir orders.

- Expert Logistical & Export Capabilities: The journey from the China souvenir factory to your warehouse can be fraught with complexities. Strategic sourcing involves partnering with a supplier who possesses deep expertise in souvenir import logistics, efficiently navigating customs regulations, optimizing shipping methods, and minimizing freight costs and potential delays. This ensures your wholesale souvenirs arrive safely, on time, and within budget.

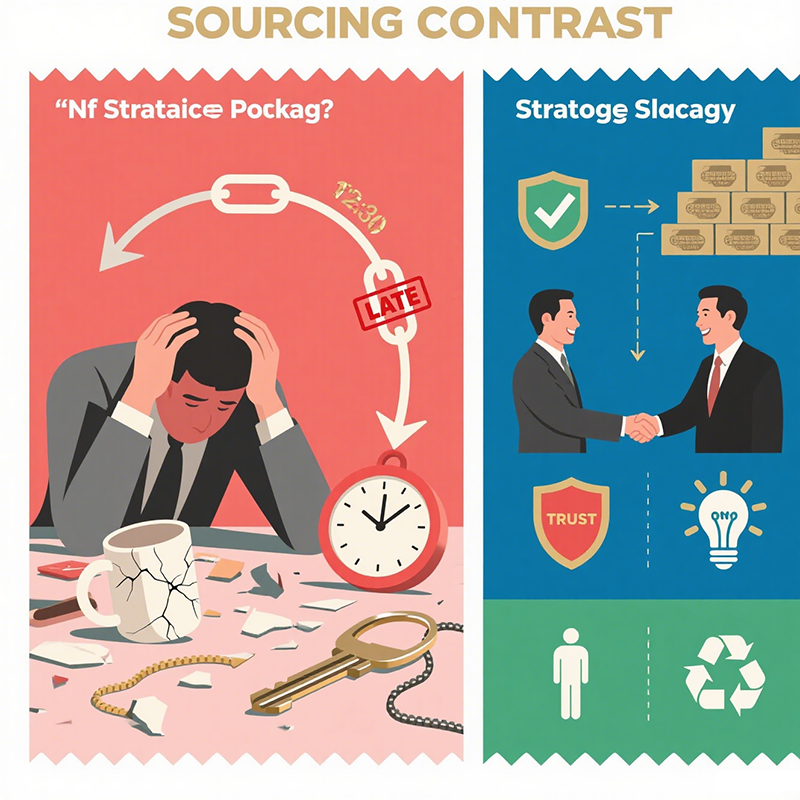

The True Cost of Non-Strategic Sourcing: Why Shortcuts Inevitably Hurt Your Bottom Line

Many newcomers, or even some established players, unfortunately fall into the alluring but ultimately destructive trap of solely chasing the lowest unit price offered. This short-sighted, “non-strategic” approach to procurement often leads to a cascade of hidden costs and significant long-term damage that far outweigh any initial perceived savings.

- Pervasive Quality Fade & Product Failures: Prioritizing the cheapest option often means compromising on materials, workmanship, and souvenir quality control. This invariably results in inconsistent batches, higher defect rates (products that are broken, poorly finished, or not as advertised), leading to a surge in customer complaints, costly product returns, negative reviews, and irreparable damage to your brand’s hard-earned reputation for wholesale souvenirs. This quickly erodes any semblance of profit optimization you hoped to achieve.

- Crippling Production Delays & Missed Market Opportunities: Unreliable factories, often chosen for their low prices, frequently miss deadlines due to poor planning, inadequate capacity, or insufficient skilled labor. These delays cause painful stockouts, result in significant lost sales revenue, and mean you miss critical market windows, particularly devastating for highly seasonal travel retail souvenirs or time-sensitive promotional items. The cost of a lost season is often immeasurable.

- Exorbitant Hidden Costs from Errors & Reworks: Communication breakdowns due to language barriers, cultural differences, or a lack of transparency often lead to costly misunderstandings, incorrect product specifications, or entire batches requiring rework or even scrapping. This adds significant unforeseen expenses and extends lead times, impacting your profit optimization.

- Catastrophic Ethical & Environmental Reputational Risks: Sourcing from unvetted factories can expose your brand to immense reputational damage if they are found to be engaging in unethical labor practices (e.g., child labor, unsafe working conditions) or unsustainable manufacturing (e.g., severe pollution, illegal waste dumping). In today’s interconnected world, such exposures can lead to consumer boycotts, retailer delisting, and severe brand tarnishment, making ethical sourcing and green souvenir manufacturing non-negotiable for international compliance.

- Logistical Nightmares & Unforeseen Expenses: Solely focusing on factory gate price ignores the complexities of souvenir import logistics. Unforeseen customs issues, higher-than-expected freight costs due to poor packaging or inefficient shipping methods, and damaged goods due to inadequate protection can add significant, unanticipated expenses to your bulk souvenir orders, turning a supposed gain into a significant financial drain.

These pervasive hidden costs can very quickly and dramatically negate any initial savings gained from a seemingly lower unit price, effectively turning a supposed gain into a significant financial drain and an immeasurable reputational loss. The truly successful brands we will examine in the following case studies inherently understood this fundamental truth early on in their journey.

Case Study 1: “Destination Delights” – Dominating the Niche Market with Bespoke Collectibles

Background: “Destination Delights” (a carefully constructed fictionalized example, yet one that powerfully represents a very real and thriving trend within the global souvenir market) started as a relatively small, ambitious brand retailer. Their unique vision was to meticulously focus on creating high-end, truly collectible customized souvenirs specifically tailored for iconic, globally recognized tourist attractions, moving far beyond the realm of generic, mass-produced trinkets. Their core premise was to capture the distinct essence and architectural grandeur of each landmark in exquisite detail. They quickly identified a critical bottleneck: their local, domestic suppliers simply couldn’t meet the intricate design demands, the precise material specifications, or the necessary scalability for large quantity souvenir production required to fulfill their ambitious vision.

The Strategic Sourcing Play: Precision, Collaboration, and Gradual Scaling for Perfection

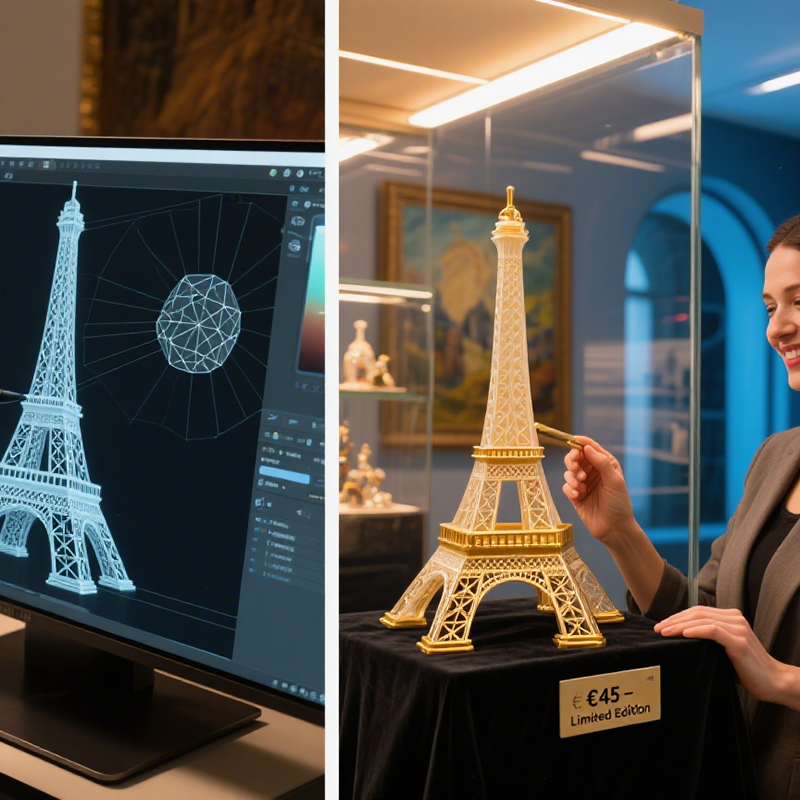

“Destination Delights” understood that their product’s unique value lay in its unparalleled detail and quality. They didn’t just search for “a factory”; they actively sought a souvenir supplier China with specialized capabilities in fine detail work, advanced molding techniques, and a proven track record as a highly skilled resin souvenir manufacturer. Their sourcing strategy was meticulously focused on cultivating a deeply collaborative partnership:

- Design-First, Iterative Partnership: Rather than merely sending over a 2D logo or a simple sketch, “Destination Delights” engaged in extensive, iterative collaboration on every stage of souvenir product development. The chosen China souvenir factory distinguished itself by possessing robust in-house capabilities for precise 3D modeling (CAD/CAM) and rapid prototyping (including 3D printing). This allowed for multiple, rapid iterations of intricate designs (e.g., highly detailed miniature architectural replicas of famous landmarks, bespoke character figurines unique to specific attractions). This meticulous design validation process ensured absolute fidelity to the original artistic vision for every resin craft for souvenir.

- Emphasis on Prototype Perfection & “Golden Samples”: They understood that investing time and resources upfront was critical. They dedicated significant effort and financial investment to the prototyping phase, demanding multiple “golden samples.” This painstaking process ensured that every minute curve, precise color match (verified against Pantone standards), and exact texture of the resin craft for souvenir met their extremely high standards before they even considered approving bulk souvenir orders. This meticulous approach to souvenir quality control at the very beginning of the production cycle proved invaluable, preventing incredibly costly reworks, delays, and material waste later in large scale manufacturing.

- Controlled, Gradual Scaling with Performance Benchmarks: To mitigate risk and ensure consistent quality, “Destination Delights” initiated their manufacturing partnership with manageable MOQ 1200 PCS orders for specific, high-demand, hero items. This allowed them to thoroughly test the market, verify the factory’s consistent output quality, and build mutual trust. Only after demonstrating consistent performance and meeting stringent souvenir quality control metrics did they confidently scale up to massive, multi-SKU production runs across numerous designs and destinations.

The Empire Built: Premium Positioning and Unrivaled Market Share

Through this meticulous and strategic sourcing approach, “Destination Delights” has blossomed. They now boast an impressive portfolio of over 50 unique, highly collectible customized souvenir lines spanning major global landmarks, from the Eiffel Tower to the Statue of Liberty. Their products command premium prices in the market, not just due to their intricate detail and superior quality, but also because of the scarcity of truly high-fidelity travel retail souvenirs. Their sterling reputation for producing unique, consistently high-quality souvenir crafts has made them the undisputed preferred supplier for prestigious museum gift shops, national park concessions, and world heritage sites globally. Their remarkable success is a powerful testament to the fact that genuine profit optimization in the souvenir industry comes from unwavering perceived value, brand differentiation, and a meticulously cultivated manufacturing partnership built on expertise, rather than simply chasing the lowest possible unit cost.

Case Study 2: “Global Gear” – Achieving Market Leadership Through Unwavering Quality and Ethical Sourcing

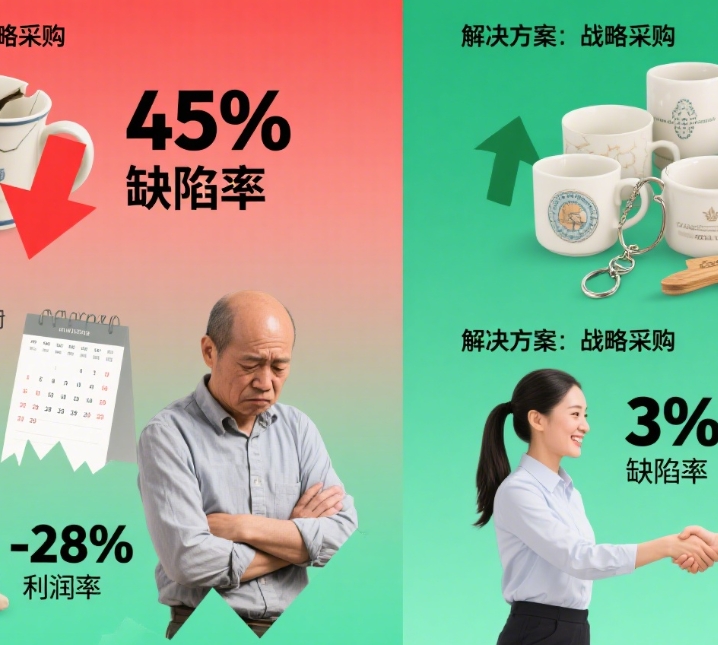

Background: “Global Gear” (representing a common, yet increasingly challenging, trajectory for wholesale souvenir distributors) initially entered the market with a broad focus on functional, everyday travel souvenirs like destination-themed keychains, practical bottle openers, and iconic magnets. In their early phases, they faced common and debilitating challenges: rampant quality inconsistency from multiple, disparate small-scale suppliers, leading directly to unacceptably high return rates, constant customer complaints, and significant damage to their fledgling brand reputation. They quickly recognized that to genuinely scale their operations and capture significant market share for bulk souvenir orders, they needed not just volume, but unflappable, reliable quality, coupled with a commitment to responsible production.

The Strategic Sourcing Play: Integrity, Transparency, and Long-Term Partnership for Reliability

“Global Gear” made a profound and strategic shift in its sourcing paradigm. They deliberately moved away from short-term, price-driven supplier relationships and prioritized forging a manufacturing partnership with a souvenir supplier China that possessed a proven, demonstrable track record for robust souvenir quality control and an unwavering, transparent commitment to ethical sourcing. Their investment in this new strategy was deep and thorough:

- Rigorous and Comprehensive Factory Audits: Before placing any substantial large quantity souvenir production, “Global Gear” implemented a strict protocol of comprehensive, independent, on-site factory audits. These audits went far beyond mere production capabilities; they meticulously assessed labor practices (demanding evidence of compliance with standards like BSCi or Sedex SMETA), scrutinized environmental management systems (requiring ISO 14001 certification or equivalent), and reviewed workplace safety protocols. This rigorous due diligence gave “Global Gear” immense confidence in their supplier’s green souvenir manufacturing claims and overall operational integrity.

- Integrated Quality Assurance Protocols: They didn’t just rely on final inspection. They chose a China souvenir factory that demonstrated an ingrained, end-to-end quality assurance system that spanned the entire production lifecycle: Incoming Quality Control (IQC) for all raw materials (e.g., metal purity for iron art souvenir China, paint pigment consistency), In-Process Quality Control (IPQC) at every critical stage of manufacturing (e.g., molding, plating, assembly), and a thorough Pre-Shipment Inspection (PSI) before dispatch. For their iron art souvenir China items, this meant meticulous checks at every granular stage, from metal purity and casting integrity to plating thickness, enamel application, and paint adhesion.

- Fostering a Long-Term Partnership Mentality: Rather than engaging in purely transactional buying, “Global Gear” actively fostered a manufacturing partnership built on shared values, mutual respect, and a commitment to continuous improvement. They actively communicated detailed market feedback, invested collaboratively in joint process optimization initiatives, and offered stable, long-term contracts. This strategic stability allowed the souvenir supplier China to confidently invest in cutting-edge equipment, advanced training for their workforce, and improved infrastructure, further enhancing both product quality and overall production efficiency, especially crucial for bulk souvenir orders.

- Leveraging a Transparent Supply Chain for Marketing Advantage: The commitment to ethical sourcing and international compliance became a powerful marketing asset for “Global Gear.” They were able to transparently communicate their responsible sourcing practices to their B2B clients, providing verifiable audited reports and even inviting key retail partners on virtual factory tours. This unparalleled transparency gave them a significant competitive edge in a market that is increasingly demanding accountability, sustainability, and ethical production practices, particularly for wholesale souvenirs.

The Empire Built: Unmatched Reputation and Dominant Market Presence

By making this profound shift to a strategic sourcing model, “Global Gear” rapidly grew to become a leading wholesale souvenir distributor for major theme parks, extensive airport retail chains, and prominent tourist attractions across multiple continents. Their unblemished reputation for consistent, high-quality, and demonstrably ethically sourced travel souvenirs allowed them to secure highly lucrative, premium contracts that were out of reach for their less discerning competitors. Their drastically reduced defect rates, minimal customer returns, and significantly lower warranty claims directly translated into substantial boosts in their profit optimization. “Global Gear” definitively proved that making a strategic investment in true product quality and transparent ethical sourcing is not merely a cost center, but a powerful, sustainable engine for empire-building in the global souvenir market, particularly for large-scale bulk souvenir orders.

Case Study 3: “Urban Artisans” – From Local Craft to Global Scale with Digital Design and Blended Manufacturing

Background: “Urban Artisans” began its journey as a small, passionate collective of artists and designers, meticulously crafting customized souvenirs that drew deep inspiration from the unique architectural styles and cultural landmarks of various urban centers. Their initial products, while exquisitely handcrafted and possessing undeniable artistic merit, inherently suffered from significant limitations: they simply couldn’t scale their production to meet national, let alone burgeoning international, demand for large quantity souvenir production. They constantly struggled with output inconsistencies inherent in pure manual production, painfully high labor costs for intricate detailing, and the inability to quickly replicate designs across thousands of units with perfect fidelity.

The Strategic Sourcing Play: Harmonizing Artistry with Advanced Manufacturing for Scale

The breakthrough moment for “Urban Artisans” came from a bold embrace of cutting-edge digital manufacturing technologies and a strategic decision to partner with a souvenir supplier China that not only excelled in this domain but also deeply understood how to blend traditional craftsmanship with modern efficiency. They specifically sought a factory that could act as a true extension of their artistic vision, combining precision technology with skilled hand-finishing:

- Seamless Digital Design & Prototyping Integration: Their initial, labor-intensive handcrafted designs were meticulously translated into precise 3D digital models (CAD/CAM files). This digital blueprint then allowed the chosen China souvenir factory to leverage advanced Computer Numerical Control (CNC) machines for exquisitely carving wooden souvenir China pieces with perfect symmetry, or to create highly detailed, flawless molds for intricate ceramic souvenir production or complex resin craft for souvenir items. This digital precision ensured perfect replication and consistency across thousands of units, a feat impossible with purely manual methods. This significantly accelerated souvenir product development cycles.

- Preserving Artisan Touch Through Scalable Hand-Finishing: Crucially, while machines handled the high-precision, repetitive work, “Urban Artisans” ensured their manufacturing partnership still incorporated highly skilled artisans for the final, critical touches. This included meticulous hand-painting of intricate details, applying specific distressing techniques to give a vintage feel, or performing delicate assembly, thereby preserving the unique “artisan” feel and aesthetic that was core to their private label souvenirs—but now achieved efficiently at large scale manufacturing. This blend was pivotal for maintaining their premium brand identity.

- Building Supply Chain Resilience Through Diversified Capabilities: Their chosen souvenir supplier China was not a single-line factory; it boasted multiple, diversified production lines and established relationships with various raw material sourcing partners. This inherent flexibility and redundancy proved absolutely invaluable during periods of global supply chain disruptions (e.g., pandemic-related lockdowns, shipping container shortages). This built-in resilience in their global souvenir supply chain and strategic flexibility in souvenir import logistics and production scheduling allowed “Urban Artisans” to maintain consistent stock levels and meet delivery commitments even when many competitors faced severe, crippling delays and lost sales.

The Empire Built: Artistic Integrity at Unprecedented Scale

Through this visionary approach to strategic sourcing, “Urban Artisans” successfully scaled their operations from a local craft collective to a formidable player. They transitioned seamlessly from producing small, bespoke batches to fulfilling significant bulk souvenir orders for national museum gift shops, major art gallery chains, and even prestigious international department stores. Their products, while now mass-produced, remarkably retained their unique artistic appeal and perceived handcrafted quality, thanks to the harmonious blend of digital precision and meticulous artisanal finishing. This ability to deliver consistent quality and design integrity at large quantity souvenir production volumes unlocked unprecedented growth and remarkable profit optimization, firmly establishing “Urban Artisans” as a dominant and respected player in the art-inspired travel souvenir segment.

The Strategic Sourcing Payoff: Quantifying the Benefits for Bulk Souvenir Orders

These compelling case studies are not isolated incidents; they represent a widespread pattern of success achieved through strategic sourcing. The benefits derived from such an approach for bulk souvenir orders are not merely anecdotal; they are profoundly quantifiable and remarkably significant for any tourism souvenir importer, wholesaler, or brand retailer. Let’s concretely examine a hypothetical, yet highly realistic, comparison for a wholesale souvenir company placing a substantial bulk souvenir order of 10,000 units (e.g., resin fridge magnets or wooden keychains), juxtaposing a non-strategic (solely lowest unit price) approach versus a value-driven, strategic manufacturing partnership.

| Metric / Outcome | Non-Strategic Sourcing (Lowest Price Focus – Risk-Prone) | Strategic Sourcing (Value-Driven Partnership – Resilient) | Tangible Impact per 10,000 Units (Illustrative Savings/Gains) |

| Defect Rate (at inbound QA) | 5% – 10% (due to poor souvenir quality control, inconsistent inputs) | 0.5% – 2% (due to robust IQC, IPQC, PSI) | Reduced 300-800 defective units, saving material & rework costs (est. $1,500 – $4,000 @ $5/unit). Directly boosts profit optimization. |

| Production Delays (Avg.) | Frequent (2-4 weeks due to reworks, poor planning, communication gaps) | Rare (on-time delivery, clear communication, proactive issue resolution) | Avoided 2-4 weeks of missed sales (potential revenue opportunity of $X,XXX – $XX,XXX). Prevents stockouts & strengthens retailer relations. |

| Hidden Costs (Rework, Returns, Claims) | High (shipping returns, chargebacks from retailers, expedited freight for replacements) | Low (minimal returns, high customer satisfaction, fewer claims) | Reduced $500 – $1,500+ in return freight, re-shipping, handling fees, and customer service resources. |

| Brand Reputation & Loyalty | Severely damaged (customer complaints, negative online reviews, retailer dissatisfaction) | Significantly enhanced (consistent quality, positive feedback, high customer retention) | Increased customer loyalty & repeat orders, intangible long-term brand value. Attracts new, quality-conscious brand retailers. |

| Supplier Communication Efficacy | Fragmented, reactive, prone to misunderstandings, cultural barriers | Proactive, clear, collaborative, professional, responsive | Saved 10-20 hours/month in management and troubleshooting time, avoiding costly errors and frustrations. |

| Logistics Issues & Unforeseen Costs | Frequent (customs holds, shipping damage due to poor packaging, unexpected surcharges) | Minimal (smooth souvenir import logistics, proper documentation, optimized shipping) | Reduced $200 – $800+ in shipping claims, demurrage fees, and the need for expensive expedited freight. |

| Overall Profit Optimization | Stagnant or Potentially Declining Margins | Significant & Sustainable Growth in Margins | Conservative Net Gain: $2,000 – $6,000+ per 10,000 units (very conservative, often much higher when factoring in lost sales & brand equity). |

| Market Access & Opportunity | Limited (only able to compete on price in saturated channels) | Expanded (access to premium retailers, brand-conscious buyers, new international markets) | Opened doors to higher-margin sales channels and significant market expansion for wholesale souvenirs. |

Export to Sheets

Note: The specific figures in this table are illustrative and based on typical industry experiences and averages. Actual savings and gains will naturally vary widely depending on specific product complexity, the existing operational inefficiencies of your business, the unit cost of the product, and prevailing market conditions. However, the directional impact remains consistently clear and universally applicable: strategic sourcing provides a measurable, substantial, and sustainable return on investment that far outstrips any perceived initial savings from purely price-driven decisions.

This table unequivocally demonstrates that while the initial unit price might seem appealing with non-strategic sourcing, the cumulative hidden costs, lost opportunities, and profound damage to your brand reputation far outweigh any perceived short-term savings. Strategic sourcing is not merely an expense; it is a critical, long-term investment that pays substantial dividends, leading directly to sustainable growth, resilient operations, and robust profit optimization for your wholesale souvenirs business.

Blueprinting Your Empire: Actionable Sourcing Steps for Bulk Buyers

Inspired by these powerful success stories and the quantifiable benefits? Here’s a practical, actionable blueprint for tourism souvenir importers, wholesalers, and brand retailers to implement their own comprehensive strategic sourcing plan for bulk souvenir orders with a premier souvenir supplier China. This isn’t just theory; it’s a step-by-step guide to transforming your procurement.

Step 1: Define Your Sourcing Goals Beyond Just Price (The “Why” and “What”)

Before you even consider reaching out to potential suppliers, invest critical time in internally clarifying what truly matters for your brand, your product line, and your long-term business vision. This internal alignment is crucial.

- Precise Product Specifications: Go far beyond basic dimensions and quantities. Specify acceptable quality ranges (e.g., AQL standards), exact material compositions and certifications (e.g., FSC-certified wood for wooden souvenir China, GRS-certified recycled resin for a resin souvenir manufacturer), critical color consistency (using Pantone codes), and all intricate finishing details (e.g., paint durability, magnet strength, surface smoothness). Provide engineering drawings or 3D models when possible.

- Non-Negotiable Supplier Requirements: Clearly list the essential certifications and capabilities your ideal China souvenir factory must possess. Are ISO 9001 (quality), ISO 14001 (environmental), and social compliance audits (BSCI, Sedex SMETA for ethical sourcing) non-negotiable? What level of communication, transparency, and reporting do you expect? Do they need to have specific expertise in particular souvenir craft types (e.g., highly specialized ceramic souvenir production, intricate iron art souvenir China)?

- Clear Timeline & Scalable Capacity: Precisely define your required lead times for large quantity souvenir production, factoring in design, prototyping, production, and souvenir import logistics. Communicate any seasonal peaks or promotional periods. Does the factory possess the proven capacity and flexibility to scale production up or down to reliably meet your fluctuating bulk souvenir orders? Inquire about their production redundancy.

- Unwavering Sustainability & Ethical Stance: If green souvenir manufacturing and ethical sourcing are core to your brand’s values, articulate these requirements from the absolute outset. Ask for verifiable proof of their commitment to environmental responsibility and fair labor practices.

Step 2: Vet Potential Souvenir Suppliers China Rigorously (The “Who”)

This critical stage is where you separate merely transactional suppliers from truly strategic manufacturing partnership candidates. Don’t cut corners here.

- Deep Dive into Portfolios & Core Capabilities: Don’t just glance at generic product photos on a website. Request detailed case studies of similar projects they’ve completed. Discuss their specific manufacturing processes in depth (e.g., their molding techniques for wholesale customized resin souvenir China, or their carving and finishing for wooden souvenir China). Inquire about their in-house R&D capabilities for new souvenir product development and their capacity for custom innovation.

- Verify Certifications & Conduct Independent Audits: Always, always request valid and up-to-date copies of all relevant certifications (quality, environmental, social). For any significant bulk souvenir orders, a third-party factory audit by a reputable inspection agency (e.g., SGS, Intertek, Bureau Veritas) is a non-negotiable, essential investment. This directly validates their claims regarding souvenir quality control, green souvenir manufacturing, and international compliance.

- Assess Communication & Responsiveness Prowess: Pay close attention to how quickly, clearly, and proactively they respond to your inquiries during the vetting process. Do they truly understand your needs? Are they proactive in offering solutions or insights? Do they speak your language (both literally and figuratively, understanding your business context)? Effective and transparent communication is the absolute bedrock of a good, reliable manufacturing partnership.

- Request Comprehensive Prototypes & “Golden Samples”: Insist on receiving detailed pre-production samples that precisely match your agreed-upon specifications. Critically evaluate these samples for quality, design fidelity, and functionality. This is your final, crucial checkpoint before committing to large scale manufacturing for your wholesale souvenirs.

Step 3: Foster a True Manufacturing Partnership, Not Just a Transaction (The “How to Work Together”)

The most successful and resilient relationships in global souvenir supply chain management are built on mutual investment, transparency, and profound trust.

- Cultivate Transparent, Ongoing Communication: Be open and honest with your chosen souvenir supplier China. Share your long-term vision, provide detailed market feedback on their products, and openly discuss any challenges you face in your market. A truly strategic China souvenir factory partner can often offer invaluable insights and solutions if they genuinely understand your broader context and goals.

- Establish Regular Performance Reviews & KPIs: Don’t just set it and forget it. Establish clear Key Performance Indicators (KPIs) for critical metrics such as quality consistency (defect rates), on-time delivery percentages, communication responsiveness, and adherence to sustainability goals. Conduct periodic reviews (e.g., quarterly or bi-annually) to discuss performance, identify areas for continuous improvement, and collectively celebrate successes.

- Embrace Joint Problem Solving: In any complex global souvenir supply chain, issues will inevitably arise. When they do, approach them collaboratively. Work constructively with your China souvenir factory partner to identify the root causes of problems and implement effective corrective and preventive actions, rather than simply assigning blame. This proactive, collaborative approach significantly strengthens the manufacturing partnership and the overall resilience of your supply chain.

- Practice Fair & Sustainable Business Practices: Honor your commitments. Pay on time. Work collaboratively on profit optimization strategies that genuinely benefit both parties, not just one. This includes actively supporting your supplier’s efforts in green souvenir manufacturing, ethical sourcing, and continuous operational improvements. A mutually beneficial relationship is a lasting one.

Step 4: Leverage Technology for Unprecedented Supply Chain Efficiency (The “Tools”)

Modern strategic sourcing benefits immensely from the intelligent adoption of digital tools and technology throughout the global souvenir supply chain.

- Digital Design & Prototyping Power: Fully utilize advanced software for CAD/CAM (Computer-Aided Design/Manufacturing), 3D printing for rapid physical prototyping, and virtual sampling tools. These technologies can dramatically streamline souvenir product development cycles, reduce the number of costly physical sample iterations, and ensure design accuracy for customized souvenirs.

- Integrated Communication & Project Management Platforms: Implement and utilize shared project management tools (e.g., Asana, Trello, Monday.com) or dedicated communication platforms. These tools enable clearer communication, centralized file sharing, transparent progress tracking, and efficient task management with your souvenir supplier China, significantly reducing miscommunications and improving oversight of bulk souvenir orders.

- Advanced Logistics Management Systems: Employ sophisticated software and systems to meticulously track your shipments in real-time, efficiently manage all necessary customs documentation, and optimize shipping routes and methods for your souvenir import logistics. This ensures smooth, timely, and cost-effective delivery of your wholesale souvenirs, minimizing delays and unexpected expenses.

- Data Analytics for Performance Insights: Utilize data analytics tools to track supplier performance, quality trends, and cost fluctuations. This data-driven approach allows for continuous refinement of your strategic sourcing decisions and identifies opportunities for ongoing profit optimization and efficiency improvements in your large quantity souvenir production.

Conclusion: Your Path to Building a Souvenir Empire

Building a truly thriving and resilient souvenir empire in today’s increasingly competitive and ethically conscious global souvenir market is not merely a lofty aspiration; it is an entirely achievable reality for tourism souvenir importers, wholesalers, and brand retailers. It’s not about relying on magic or luck; it’s about making deliberate, informed, and truly strategic sourcing decisions that prioritize long-term value over short-term gains.

By consistently prioritizing a robust, long-term manufacturing partnership over transient, price-driven transactions, by proactively investing in stringent souvenir quality control processes, by transparently embracing ethical sourcing and green souvenir manufacturing, and by strategically leveraging the advanced capabilities of a truly collaborative souvenir supplier China, you can unlock unprecedented growth, achieve sustainable profit optimization, and build a reputation for excellence that sets you apart.

At Craft Manufacturer China, we fundamentally believe that our ultimate success is intrinsically linked to yours. We have meticulously built our operations on the very pillars of strategic sourcing: unparalleled expertise in souvenir product development, rigorous, end-to-end souvenir quality control (encompassing everything from the intricate details of a resin craft for souvenir to the precision of wooden souvenir China), reliable and scalable large quantity souvenir production, an unwavering commitment to both ethical sourcing and green souvenir manufacturing, and seamless souvenir import logistics support. We don’t just supply products; we partner with you to build lasting success.

Ready to transform your sourcing strategy and embark on the journey to build your own remarkable souvenir empire? Reach out to us today. Let’s discuss how our proven expertise in handling bulk souvenir orders (especially those crucial MOQ 1200 PCS and beyond) can become the unwavering foundation of your next great success story in the global souvenir market.

- The Definitive 7-Point Checklist for Vetting a Chinese Custom Souvenir Manufacturer - January 7, 2026

- Minimum Order Quantity (MOQ) Strategies: Balancing Cost Efficiency and Market Testing for New Private Label Souvenirs - December 31, 2025

- Navigating the Tariff Landscape: Strategies for Mitigating Import Duties on Chinese-Manufactured Souvenirs - December 24, 2025