Imagine a world without the silent heroes that hold your grocery list to the fridge, power your headphones, and even drive the motors that whir silently within your electronic devices. These unsung titans are magnets, and the process that brings them to life – magnet manufacturing – is a fascinating dance between science, engineering, and a touch of industrial magic.

This article is your gateway into this captivating world. We’ll delve into the raw materials that form the foundation of magnets, explore the intricate processes that transform them from basic components into powerful forces, and unveil the diverse applications that touch nearly every aspect of our lives. So, buckle up and get ready to discover the wonders of magnet manufacturing!

Building Blocks of Magnetism: A Look at Raw Materials

Just like a delicious cake requires the perfect blend of ingredients, creating a powerful magnet starts with a specific selection of raw materials. These materials fall into two main categories:

- Magnetic Materials: These are the superstars of the show, possessing the inherent ability to generate a magnetic field. Common examples include iron, nickel, and cobalt. However, the real game-changers come in the form of rare earth elements like neodymium, which offer exceptional magnetic strength in a compact size.

- Alloying Elements: Think of these as the supporting cast. They’re often added to magnetic materials to enhance specific properties like corrosion resistance or workability. Elements like aluminum, copper, and silicon play crucial roles in creating the perfect magnetic recipe.

The specific combination of these raw materials depends on the desired properties of the final magnet. For instance, creating a powerful neodymium magnet for a high-performance electric motor requires a different recipe than crafting a decorative refrigerator magnet.

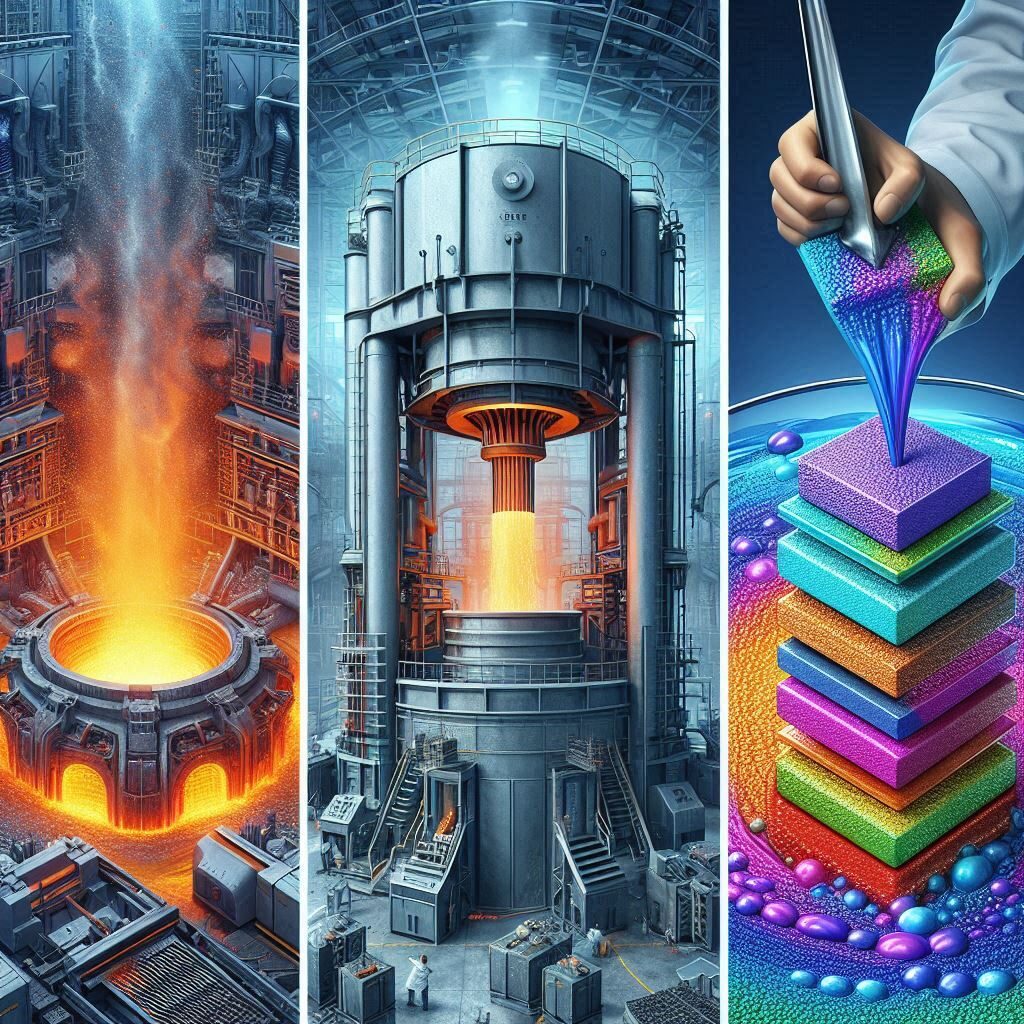

Unveiling the Magic: Three Key Methods of Magnet Manufacturing

Just like baking a cake can be done through various methods, there are several ways to manufacture magnets. Here, we’ll explore three of the most common techniques:

Sintering: The Art of Heat and Pressure

Imagine tiny grains of magnetic material coming together to form a mighty magnet. That’s the essence of sintering. Here’s how it works:

- Mixing and Melting: The raw materials are precisely measured and melted together to form a uniform alloy.

- Powder Power: The molten mixture is then rapidly cooled, transforming it into a fine powder. Think of it as creating a super concentrated magnetic dust.

- Shaping Up: The magnetic powder is then pressed into the desired shape under immense pressure. This pressing aligns the individual particles, laying the groundwork for magnetism.

- Heat Treatment: Finally, the compacted material undergoes a high-temperature “sintering” process in a controlled atmosphere. This intense heat fuses the particles together, solidifying the magnet and maximizing its magnetic strength.

Advantages: Sintering is a versatile method that can produce a wide range of magnet shapes and sizes. It also results in magnets with exceptional strength and durability.

Disadvantages: The process can be energy-intensive and requires specialized equipment. Additionally, creating intricate shapes with sintering can be more challenging.

Types of Magnets Produced: Sintering is widely used for permanent magnets, particularly those made with rare earth elements like neodymium. These magnets find applications in everything from loudspeakers and electric motors to MRI machines and wind turbines.

Melting and Casting: Shaping the Magnetic Force

This method offers a more direct approach to creating magnets. Here’s the process:

- Molten Magic: The raw materials are melted together to form a hot, liquid alloy.

- Molding the Future: The molten metal is then poured into pre-designed molds. As it cools and solidifies, it takes the shape of the mold, creating the final magnet.

- Cooling Down: Once the metal has solidified, the magnet is removed from the mold and allowed to cool completely.

Advantages: Melting and casting is a relatively simple and cost-effective method. It’s particularly suitable for producing large, simple-shaped magnets.

Disadvantages: The magnetic strength of magnets produced through this method can be lower compared to those created through sintering. Additionally, controlling the cooling process can be crucial for achieving the desired magnetic properties.

Types of Magnets Produced: Melting and casting is commonly used for creating ferrite magnets, a type of ceramic magnet known for its affordability and resistance to corrosion. These magnets are widely used in applications like speakers, toys, and magnetic closures.

Beyond the Basics: A Deep Dive into Manufacturing Processes

Each of the methods mentioned above involves a series of additional stages to ensure the creation of high-quality magnets. These stages can include:

- Milling: Grinding the raw materials into a fine powder before sintering or mixing them with resin for bonded magnets.

- Machining: Shaping the finished magnet to achieve precise tolerances and dimensions.

Different Types of Magnets and Their Manufacturing Processes

The world of magnets is far more diverse than just sticking notes to the fridge door. Here, we’ll explore the manufacturing processes behind some of the most common types:

Manufacturing Process of Common Magnets:

These everyday heroes, often found on refrigerators or used for closures, are typically produced using the melting and casting method. Ferrite magnets, known for their affordability and resistance to demagnetization, are a popular choice for these applications. The manufacturing process involves:

- Melting iron oxide and barium carbonate to form a molten mixture.

- Pouring the molten material into molds shaped like the desired magnets.

- Allowing the mixture to cool and solidify, taking the shape of the mold.

- Grinding and polishing the finished magnets for a smooth finish (optional).

Manufacturing of Neodymium Magnets:

hese powerful magnets, often composed of neodymium, iron, and boron, are the workhorses of modern technology. They are typically manufactured using the sintering method due to their need for exceptional strength:

- Precisely measuring and melting neodymium, iron, and boron to form a uniform alloy.

- Rapidly cooling the molten mixture to create a fine neodymium-iron-boron powder.

- Pressing the powder into the desired shape under high pressure to align the magnetic particles.

- Sintering the compacted powder at high temperatures to solidify the magnet and maximize its strength.

- Electroplating the finished magnet with a protective layer to prevent corrosion.

Manufacturing of Permanent Magnets:

Permanent magnets, as the name suggests, retain their magnetism indefinitely. They are most commonly produced through sintering or a variation called hot deformation, where the hot, malleable material is pressed into shape before sintering. Neodymium magnets, ferrite magnets, and samarium-cobalt magnets (known for their high-temperature resistance) are all examples of permanent magnets.

Quality Control in Magnet Production: Ensuring Magnetic Might

Just like any high-performance product, magnets need to meet stringent quality standards. Here’s how manufacturers ensure their creations are up to par:

- Chemical Composition Analysis: Verifying the precise composition of the raw materials used to ensure they meet the desired specifications.

- Dimensional Inspection: Measuring the finished magnets to guarantee they conform to the exact dimensions required for the application.

- Magnetic Performance Testing: Evaluating the magnetic strength and other magnetic properties of the finished magnets to ensure they meet the required specifications. This may involve using specialized equipment like magnetometers.

- Surface Inspection: Checking the surface of the magnets for any defects or imperfections that could affect their performance or aesthetics.

Applications of Magnets: A Magnetic Force in Our World

The influence of magnets extends far beyond refrigerator decorations. They are essential components in a vast array of industries, shaping our everyday lives:

- Consumer Electronics: From the tiny speakers in your smartphone to the motors that power your hard drive, magnets are the silent heroes behind many of our electronic devices.

- Electric Vehicles: The powerful electric motors driving the future of transportation rely on high-strength magnets to generate torque and propulsion.

- Medical Technology: MRI machines utilize powerful magnets to create detailed images of the human body, aiding in medical diagnosis.

- Manufacturing: Magnets are used in countless industrial applications, from separating metals in recycling plants to holding tools in place during manufacturing processes.

- Renewable Energy: Wind turbines rely on magnets in their generators to convert wind energy into electricity.

This is just a glimpse into the diverse applications of magnets. Their ability to generate invisible forces makes them invaluable tools across various sectors.

Challenges and Future Trends in Magnet Manufacturing

The future of magnet manufacturing is brimming with both challenges and exciting possibilities:

- Environmental Concerns: Mining rare earth elements used in high-performance magnets can have environmental consequences. Finding sustainable sourcing and recycling methods is crucial.

- Supply Chain Issues: Geopolitical factors can disrupt the supply chain for certain raw materials, impacting magnet production costs and availability.

- Advancements in Manufacturing Technologies: Researchers are constantly developing new methods for creating magnets with even higher strength and improved efficiency.

- Development of New Materials: The discovery of new magnetic materials with unique properties could revolutionize various industries.

By addressing these challenges and embracing innovation, the future of magnet manufacturing promises even more powerful and versatile magnets, shaping the technological advancements of tomorrow.

Conclusion: The Invisible Force Shaping Our World

Magnet manufacturing is more than just an industrial process; it’s a testament to human ingenuity and our ability to harness the power of nature. From the humble refrigerator magnet to the powerful motors driving electric vehicles, magnets play a vital role in our world. As we continue to explore the possibilities of magnetic materials and refine manufacturing techniques, the future promises even more exciting applications for this invisible force that shapes our lives.

FAQs

1. What are the strongest types of magnets?

Neodymium magnets (NdFeB) are currently the strongest commercially available permanent magnets. They are composed of neodymium, iron, and boron and offer exceptional magnetic strength in a compact size. However, they are also more susceptible to demagnetization at high temperatures compared to some other types of magnets.

2. Can I make magnets at home?

Yes, there are some simple experiments you can try at home to create weak magnets. These often involve inducing magnetism in materials like iron nails using electromagnets. However, creating high-strength magnets for practical applications requires specialized equipment and controlled manufacturing processes.

3. How can I dispose of old magnets safely?

Most magnets can be disposed of safely with regular household waste. However, for very large or powerful magnets, it’s recommended to check with your local recycling center or waste management authority for specific disposal guidelines.

4. Are magnets safe for children?

Small magnets can be a choking hazard for young children. It’s crucial to keep them out of reach and supervise children around any magnets, especially powerful ones.

5. What are the future applications of magnets?

The possibilities are vast! Researchers are exploring applications of magnets in areas like magnetic refrigeration, maglev transportation systems, and even targeted drug delivery in medicine. As new materials and manufacturing techniques emerge, the future holds exciting potential for magnets to play an even greater role in shaping our world.

- Resin vs. Ceramic: A Data-Driven B2B Comparison for High-Volume Souvenir Orders - February 4, 2026

- AQL 2.5 vs. 4.0: Defining Acceptable Defect Thresholds for Mass-Produced Tourist Magnets - January 28, 2026

- The Importer’s Guide to Total Landed Cost (TLC): Calculating the Real Price of Resin Souvenirs from Quanzhou - January 21, 2026