In the world of wholesale souvenirs, it’s tempting to focus solely on the per-unit price. A lower quote might look like a win on paper. But what happens when that seemingly cheap product arrives at your warehouse with defects? The low initial price is quickly forgotten, replaced by a domino effect of costly problems:

- Returns and Replacements: You have to spend time and money processing returns, issuing refunds, or sending replacements. This isn’t just a loss of profit; it’s a loss of time and resources that could have been spent on growing your business.

- Damaged Brand Reputation: In the digital age, a single batch of defective products can lead to a flood of negative reviews on social media and e-commerce platforms. This can permanently damage your brand’s reputation, deter future customers, and make it impossible to command a premium price for your souvenir crafts.

- Lost Repeat Business: Customers who receive a low-quality item are unlikely to ever buy from you again. This means you’ve not only lost a single sale, but the lifetime value of a customer. In the long run, this can be the difference between a successful enterprise and one that struggles to stay afloat in a competitive global souvenir supply chain.

- Uncertainty and Lack of Control: When you source from a souvenir supplier China that lacks a transparent quality process, you are constantly worried about what will arrive. This creates unnecessary stress and makes it impossible to plan for your business’s future with confidence.

Ultimately, a lack of robust souvenir quality control transforms a seemingly simple bulk souvenir order into a high-stakes gamble. The smartest tourism souvenir importers understand that quality is not an expense—it’s the most critical investment they can make in their business’s stability and growth.

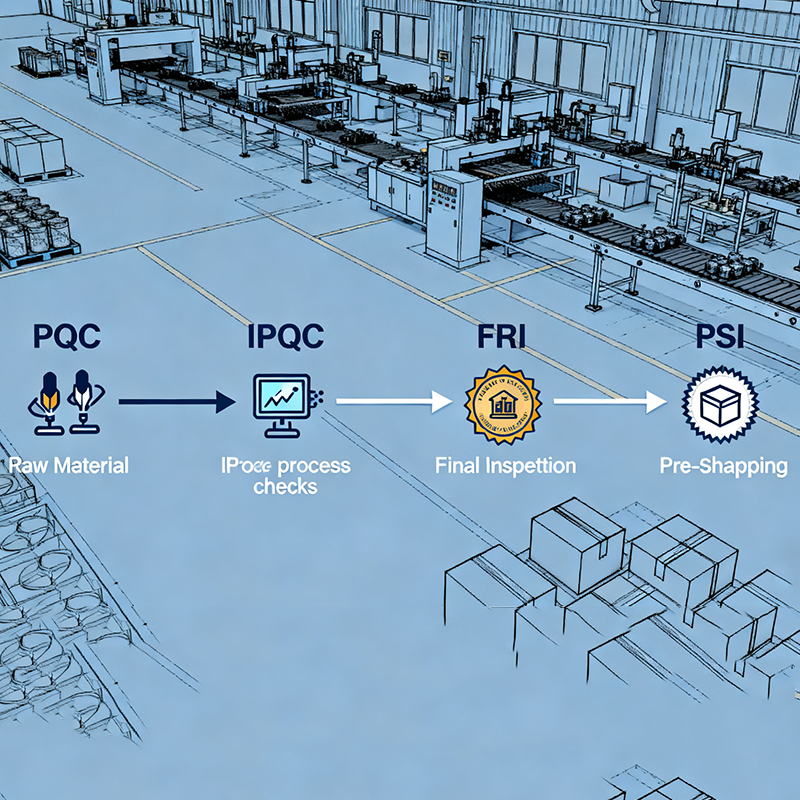

Decoding Souvenir Quality Control: A Multi-Stage Blueprint

True quality assurance is not a single, final step. It is a comprehensive, multi-layered process that is embedded into every stage of the souvenir manufacturing process. At craftmgf.com, we follow a strict blueprint that protects our clients’ interests from the moment a project begins.

Stage 1: Pre-Production Quality Check (PQC)

Before a single piece is manufactured, our quality team gets to work. This proactive approach prevents the vast majority of potential defects.

- Raw Material Inspection: We verify that all incoming raw materials—whether it’s the resin for a detailed figurine from a resin souvenir manufacturer, the metal for an intricate charm from an iron art souvenir China specialist, or the wood for a FSC-certified wooden souvenir China product—meet our strict standards and any required certifications.

- Tooling and Mold Verification: For custom projects, we conduct a thorough inspection of all molds and tooling before production begins. This ensures they are free of defects and capable of producing consistent, high-quality souvenir crafts over a large quantity souvenir production run.

Stage 2: In-Process Quality Control (IPQC)

Quality is built, not inspected. Our IPQC team performs continuous checks throughout the souvenir manufacturing process to catch issues as they occur, preventing a problem from spreading across the entire order.

- Line Inspections: We conduct random spot checks on the production line, verifying dimensions, colors, finishes, and features.

- Audits at Key Stages: Our team audits crucial stages of production, such as the molding process for a ceramic souvenir production run or the painting and finishing of a private label souvenirs order. This ensures that every step is executed perfectly before the product moves to the next phase.

Stage 3: Final Random Inspection (FRI)

This is the traditional quality check, but it’s part of a much larger system. Once a bulk souvenir order is complete, a representative sample is pulled and meticulously inspected against your approved specifications.

- AQL Standards: We follow internationally recognized AQL (Acceptance Quality Limit) standards. This scientific approach ensures that the sample size is statistically significant, providing a reliable snapshot of the quality of the entire order.

- Product Functionality & Appearance: We check every detail, from the paint application on a custom souvenirs figurine to the fit of a lid on a mug, ensuring that the product is both beautiful and functional.

Stage 4: Pre-Shipment Inspection (PSI)

This final stage of souvenir quality control ensures that your products are properly packed and ready for the complex journey of souvenir import logistics.

- Packaging Integrity: We check that the inner and outer packaging are sturdy and free from damage, ensuring your products are protected during transit.

- Labeling and Markings: We verify that all labels, barcodes, and shipping marks are accurate and clearly applied, which is essential for a smooth customs clearance and a seamless delivery process at your warehouse.

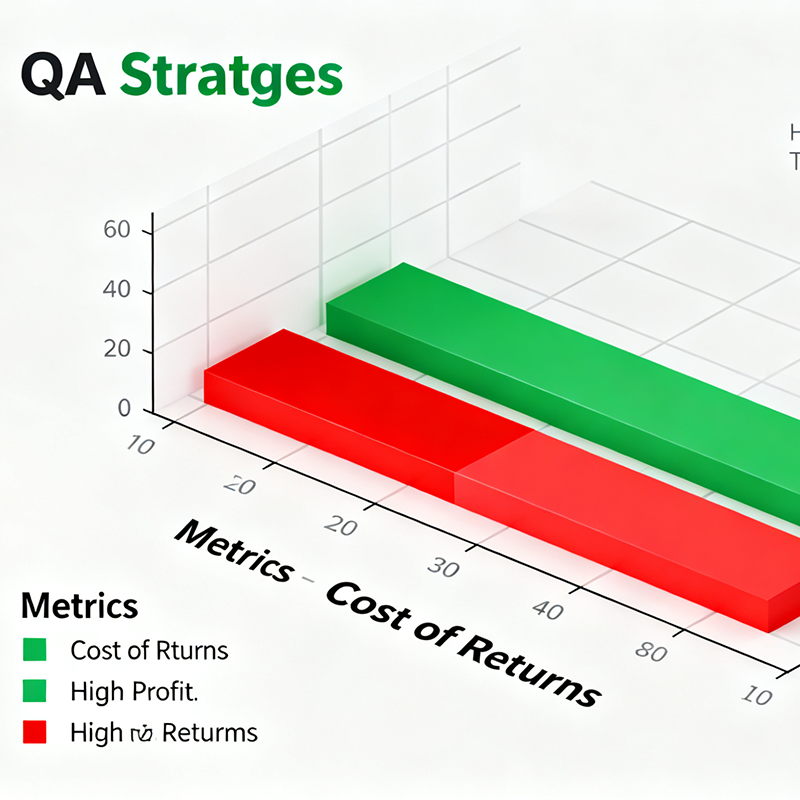

The Data: A Comparative Analysis of QA Strategies

To illustrate the tangible value of a multi-stage QA process, let’s look at the risk-reward profile of different sourcing strategies. This data is based on our industry analysis and client case studies, providing a clear guide for your strategic planning.

| QA Strategy | Upfront Cost (QA System) | Risk of Defects (per order) | Cost of Returns & Refunds | Brand Reputation Impact | Overall Profit Optimization |

| “No QA” (Trust Only) | Very Low | Very High | Very High | Severe Damage | Very Low |

| “Final Inspection Only” | Low | High | Medium-High | Potential Damage | Medium-Low |

| “Multi-Stage QA” | Medium | Very Low | Very Low | Protected & Enhanced | Very High |

Export to Sheets

Note: This data is for illustrative purposes based on industry averages. Your specific results may vary based on product complexity and order volume.

This table highlights a crucial business reality: skimping on quality control is a false economy. While a comprehensive multi-stage QA process requires a modest upfront investment, it drastically reduces your long-term business risk and protects your profit optimization. The cost of handling a single batch of defective products can be far higher than the investment in a robust quality system that prevents the problem in the first place.

The Human Element: Building a Culture of Quality

Behind every great quality control system is a commitment to excellence. The blueprint we’ve outlined is only effective when it’s executed by a team that genuinely cares about the quality of the product. This is where a strategic manufacturing partnership truly shines.

- Choosing the Right China Souvenir Factory: Quality assurance begins with a deep-dive into your potential souvenir supplier China. Look for partners with internationally recognized certifications (like ISO 9001), a track record of transparent communication, and a clear dedication to their clients’ success. At

craftmgf.com, we consider ourselves an extension of your team, and we manage the souvenir quality control as if the products were our own. - The Power of Proactive Communication: The best way to prevent quality issues is to have crystal-clear communication throughout the souvenir product development process. Our team works closely with yours, providing detailed updates, sending samples for approval at every stage, and documenting every decision. This transparency is the foundation of a trust-based manufacturing partnership.

- Continuous Improvement: A true culture of quality is one of continuous improvement. We consistently review our souvenir manufacturing process and quality control procedures to find ways to be more efficient, more reliable, and more effective for our clients. This long-term commitment is what separates a world-class factory from the competition.

Our Promise of Quality: The Craftmgf.com Difference

At Craftmgf.com, we understand that for a tourism souvenir importer, a great product is a reflection of your brand. We don’t just produce wholesale souvenirs; we build trust through a commitment to quality. Our multi-stage QA blueprint isn’t just a marketing claim—it’s a core pillar of our business philosophy.

From the first sketch to the final shipment, our dedicated team oversees every aspect of your bulk souvenir orders. Whether it’s the meticulous detail on a resin souvenir manufacturer product or the precise finish on a wooden souvenir China piece, we ensure that every item that leaves our factory is a testament to quality.

Don’t leave your brand reputation to chance. It’s time to partner with a souvenir supplier China that makes your quality concerns their top priority. Contact us today to discuss your project and discover how our commitment to souvenir quality control can protect your business and enhance your profit optimization.

- Resin vs. Ceramic: A Data-Driven B2B Comparison for High-Volume Souvenir Orders - February 4, 2026

- AQL 2.5 vs. 4.0: Defining Acceptable Defect Thresholds for Mass-Produced Tourist Magnets - January 28, 2026

- The Importer’s Guide to Total Landed Cost (TLC): Calculating the Real Price of Resin Souvenirs from Quanzhou - January 21, 2026