Navigating the global souvenir market for bulk souvenir orders can feel like a high-stakes game. For tourism souvenir importers, wholesalers, and brand retailers, the twin challenges of Minimum Order Quantities (MOQs) and achieving true cost efficiency are constant concerns. It’s not just about finding a souvenir supplier China; it’s about finding the right one that understands your volume needs (1200+ PCS), optimizes your spend, and delivers without compromising on quality.

This blueprint is designed to arm you with the strategies and insights needed to master MOQs, unlock significant cost savings, and streamline your wholesale souvenir sourcing, ensuring every dollar invested delivers maximum value.

Demystifying MOQs: Understanding the Manufacturer’s Perspective

Minimum Order Quantities (MOQs) are often seen as a hurdle, but they’re a fundamental aspect of manufacturing economics. Understanding why they exist is the first step to mastering them. For bulk souvenir orders, MOQs are directly tied to production efficiency.

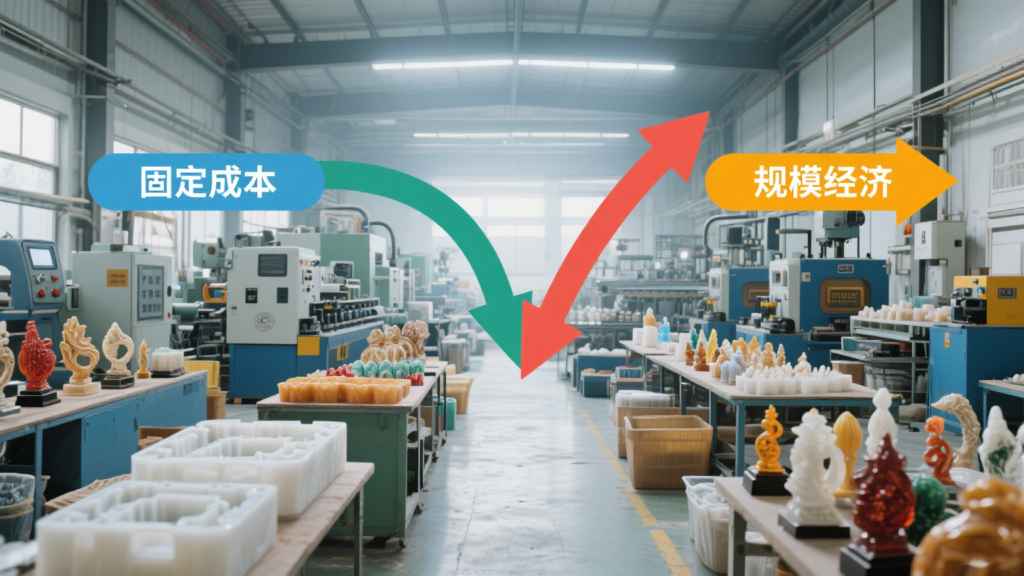

Why MOQs Exist: The Economics of Scale

Manufacturers, especially those specializing in customized souvenirs or specific materials like a resin souvenir manufacturer, set MOQs to cover their fixed costs associated with setting up a production run. These costs include:

- Tooling and Molds: Especially crucial for intricate resin craft for souvenir items or ceramic souvenir production, molds can be expensive to create. The MOQ helps amortize this cost across many units.

- Material Procurement: Suppliers offer better prices for raw materials (like specific grades of resin, wood, or metal) when purchased in larger volumes. MOQs ensure manufacturers can buy at these favorable rates, passing some of those savings onto you.

- Labor and Machine Setup: Each production run requires time for machine calibration, setup, and dedicated labor. Spreading these setup costs over a larger quantity makes each individual unit cheaper to produce, boosting the manufacturer’s efficiency.

- Waste Minimization: Larger production runs typically result in lower per-unit waste. The initial setup and calibration process might produce a few non-conforming units, but a higher volume means this initial waste is spread across more finished goods, reducing its impact on unit cost.

The MOQ Spectrum: From Flexible to Fixed

MOQs aren’t always a hard-and-fast number. They can vary significantly based on several factors, and recognizing this spectrum can give souvenir importers an edge in negotiation.

- Product Complexity: A simple, single-component resin fridge magnet manufacturer China might have a lower MOQ because their setup is quicker. In contrast, a factory producing highly intricate, multi-component iron art souvenir China items, or elaborate wooden souvenir China pieces, will likely have higher MOQs due to more complex tooling and specialized labor.

- Material Cost: If the raw material itself is expensive (e.g., precious metals, certain specialized resins, or rare woods), the MOQ might be lower in unit count but higher in total dollar value, as the manufacturer needs to recoup a significant material investment.

- Customization Level: Highly customized souvenirs that require unique molds, specific pantone color matching, or complex artwork often come with higher MOQs to justify the substantial upfront investment in custom setup and proofing. Standard designs allow for lower MOQs.

- Factory Size and Specialization: Larger China souvenir factory operations or those highly specialized in wholesale customized resin souvenir China might have higher MOQs. This is because their production lines are optimized for high-volume efficiency, and smaller runs disrupt this streamlined flow. Smaller, more flexible factories might offer lower MOQs but potentially at a higher per-unit cost.

Understanding this spectrum allows souvenir importers to better negotiate or align their purchasing strategies with manufacturer capabilities, ensuring realistic expectations from the outset.

Strategic Approaches to Mastering MOQs for Maximum Cost Efficiency

Navigating MOQs successfully means adopting smart purchasing strategies that benefit both you and your souvenir supplier China. It’s about more than just meeting the number; it’s about making the MOQ work for your bottom line.

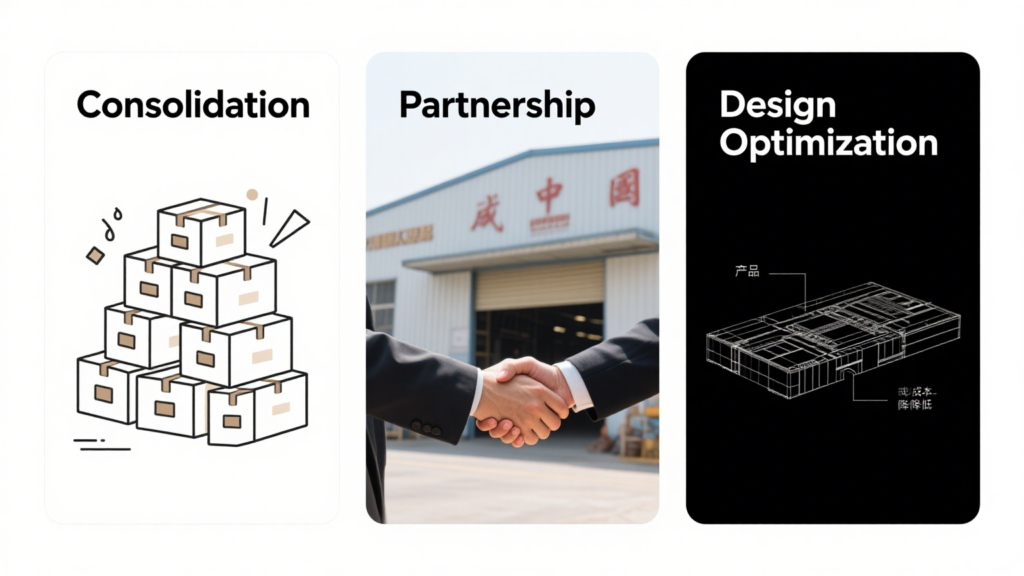

Consolidation: The Power of Grouping Orders

One of the most effective ways for wholesale souvenir buyers to manage MOQs is through order consolidation. Instead of placing separate, smaller orders for different designs or variations, combine them into one larger order that collectively meets or exceeds the manufacturer’s MOQ.

- Multiple Designs within One Material/Factory: For example, if you need 5 different resin souvenir designs, and each individually has an MOQ of 300 PCS, many manufacturers will allow you to order 600 PCS of each design (total 3000 PCS) to meet a higher overall production run MOQ. This often translates into significantly better per-unit pricing than placing 5 separate 300-PC orders, as it saves the factory on multiple setups.

- Seasonal or Themed Bundles: Plan your purchasing strategically around seasonal events (like Christmas, Halloween, or summer travel peaks) or specific themes (e.g., coastal, adventure, historical). Placing a single bulk souvenir order for all holiday-themed travel retail souvenirs will likely yield superior pricing and logistical efficiency compared to piecemeal purchases throughout the year.

- Future Planning & Forecasting: This is crucial. By accurately forecasting your needs well in advance, you can commit to larger purchase orders less frequently. Anticipating future demand for popular best-selling travel gifts allows you to hit those MOQs consistently, securing better pricing and production slots. Implement robust inventory management to support this strategy.

Negotiation Tactics: Beyond the Sticker Price

Don’t treat MOQs as absolute, non-negotiable barriers. While they’re based on economic realities for the manufacturer, there’s often significant room for discussion, especially if you position yourself as a valuable, long-term partner.

- Building Long-Term Relationships: A souvenir supplier China is far more likely to be flexible with MOQs for a long-term, reliable partner. Demonstrating consistent order volumes, clear communication, and timely payments can open doors to reduced MOQs or more favorable pricing structures in the future. It’s an investment in a collaborative manufacturing partnership.

- Trial Orders and Smaller Runs: If you’re testing a new product idea or entering a new market, propose a trial run that’s slightly below the standard MOQ. Be prepared to pay a higher per-unit price for this initial flexibility. View this as a strategic investment in validating your product’s market viability before committing to a full large quantity souvenir production. Document the terms clearly.

- Paying a Premium for Lower MOQ: Sometimes, paying a slightly higher unit price for a smaller quantity makes perfect sense if it helps you manage inventory risk, especially for new or unproven customized souvenirs. Calculate carefully if the cost of holding excess, unsold inventory outweighs the initial higher per-unit price. This is a common strategy for brand retailers launching new lines.

- Leveraging Off-Peak Seasons: Manufacturers often have slower periods. They might be more flexible with MOQs or offer better pricing during these times, as they’re eager to keep production lines running and retain skilled labor. Inquire about their production calendar.

Design Optimization for Cost Savings

The very design of your tourism souvenir can have a profound impact on its cost, especially when scaled for bulk souvenir orders. Thinking about “design for manufacturability” (DFM) is key.

- Simplifying Complexities: Intricate details, numerous small components, or complex shapes often require more labor, specialized tooling, or slower machine cycles. Small, thoughtful design tweaks that simplify these complexities can significantly reduce production costs for a resin souvenir manufacturer or a wooden souvenir craftsman. Sometimes, less is more, both aesthetically and financially.

- Material Efficiency: Design your product to minimize material waste during cutting, molding, or assembly. For example, a resin fridge magnet manufacturer China can optimize mold layouts to reduce material scrap. Similarly, efficient cutting patterns for fabric travel retail souvenirs reduce waste.

- Standardization vs. Customization Balance: While customized souvenirs are essential for brand identity, identify elements that can be standardized (e.g., a common base for different figurine designs, a standard size for customized resin crafts) while maintaining uniqueness through variable elements like color, printing, or interchangeable parts. This approach is highly effective for wholesale customized resin souvenir China where a base mold can serve many different themes.

Unlocking True Cost Efficiency: Strategies Beyond Just Unit Price

Cost efficiency in souvenir sourcing for bulk buyers goes far beyond the per-unit price. It encompasses a holistic view of your entire investment, considering quality, logistics, inventory management, and potential hidden costs that can quickly erode profits.

The Hidden Costs of Poor Quality

We touched upon this earlier, but it bears repeating with emphasis: cheap isn’t always cost-efficient. Poor souvenir quality control can lead to devastating, often unseen, hidden costs that accumulate rapidly across bulk souvenir orders.

| Hidden Cost Factor | Direct & Indirect Impact on Bulk Souvenir Orders (1200+ PCS) | Mitigation Strategy with Robust QA |

| Defective Products | Waste of raw materials, wasted production time, loss of salable goods, potential need for emergency re-production (higher cost). | Pre-shipment inspection (PSI), Initial Production Check (IPC), and During Production Inspection (DPI) identify issues early, preventing mass defects and allowing for defect prevention. |

| Returns & Rework | Freight costs for returns, labor for inspection/repacking, potential discounts/refunds to dissatisfied retailers/consumers, handling fees. | Comprehensive in-line QA and stringent pre-shipment checks ensure products meet quality standards before leaving the factory, reducing the likelihood of returns. |

| Brand Damage & Lost Trust | Negative reviews, diminished customer loyalty, loss of future sales, reduced market share, difficulty attracting new retail partners. | Consistent quality standards, achieved through rigorous souvenir quality control, build a strong brand reputation and foster trust with both B2B and B2C customers. |

| Production Delays | Missed sales opportunities (especially seasonal), rush shipping fees, penalties from retailers for late delivery, inventory gaps. | Proactive process monitoring, early problem identification (IPC), and transparent communication with your souvenir supplier China prevent costly delays. |

| Excess Inventory | Warehousing costs, insurance, potential obsolescence if trends shift, capital tied up in unsold goods. | Accurate forecasting combined with flexible MOQ negotiations and efficient production lead times reduce the need for excessive buffer stock. |

Export to Sheets

This table unequivocally highlights that investing in a robust quality assurance global souvenir supply chain isn’t an expense; it’s a critical, proactive investment in profit optimization and supply chain risk management. It shifts your focus from firefighting to strategic growth.

Optimizing Logistics and Shipping for Wholesale Souvenirs

Logistics can often be a significant, sometimes overlooked, portion of your total landed cost. Efficient shipping for bulk souvenir orders is crucial for maintaining cost efficiency.

- Consolidate Shipments Strategically: If you’re sourcing different types of wholesale souvenirs from multiple souvenir suppliers China within the same region, explore consolidating them into one larger container. This can significantly reduce per-CBM (cubic meter) freight rates compared to multiple smaller shipments.

- Choose the Right Incoterms: Understand the implications of different Incoterms (e.g., FOB, EXW, CIF) and choose the one that offers the best balance of cost, risk, and control for your specific business model. For many tourism souvenir importers, FOB (Free On Board) is preferred as it gives them control over the freight forwarder and international shipping costs.

- Strategic Warehousing and Distribution: Optimize your warehousing strategy to minimize storage costs and efficiently manage your wholesale souvenir inventory. Consider direct-to-retailer shipping where feasible to reduce double-handling.

- Partner with Professional Freight Forwarders: Engage experienced freight forwarders who specialize in souvenir import logistics. They can navigate complex customs clearance procedures, advise on optimal shipping routes, and often secure better rates, preventing costly delays and unexpected charges.

The Value of a Long-Term Manufacturing Partnership

Building a strong, long-term manufacturing partnership with a China souvenir factory can lead to profound and sustained cost efficiencies, well beyond what short-term, transactional relationships can offer.

- Preferred Pricing and Flexibility: Loyal customers often receive better pricing structures, more flexible MOQs (especially during off-peak seasons), and priority in production scheduling. This can be invaluable during peak seasons or when urgent bulk souvenir orders arise.

- Improved Communication and Understanding: A long-standing relationship fosters a deeper understanding of your specific needs, brand standards, and evolving quality expectations. This leads to fewer miscommunications, fewer errors, and ultimately more efficient and accurate production of customized souvenirs.

- Innovation and Product Development Support: A trusted partner might offer invaluable insights into new materials, more efficient production techniques, or cost-saving design tweaks (Design for Manufacturability – DFM) during souvenir product development. This collaborative approach helps you stay ahead in the global souvenir market. For example, a specialized resin souvenir manufacturer might introduce you to a new, more durable, or cost-effective resin compound.

Case Studies: Real-World Wins in MOQ & Cost Mastery

Understanding concepts is one thing; seeing them in action provides invaluable context. Here are some scenarios showcasing how strategic MOQ management and holistic cost efficiency have paid off for tourism souvenir importers and brand retailers.

Case Study 1: The Small Importer Who Mastered Consolidation

“Voyage Vault Souvenirs,” a boutique tourism souvenir importer, initially struggled with high per-unit costs due to placing multiple small, fragmented orders for different designs from various factories. Their individual orders often fell below preferred MOQs, leading to higher prices. By strategically consolidating their wholesale souvenir gifts across themes (e.g., combining city-specific resin fridge magnets, wooden keychains, and small ceramic mugs into one larger order) with a single, versatile souvenir supplier China capable of multi-product runs, they dramatically improved their leverage. This led to a negotiated reduction in overall MOQs across product lines and, crucially, a decrease in their average per-unit cost by a remarkable 15% over two fiscal quarters. This allowed them to diversify their offerings for travel retail souvenirs without incurring excessive inventory risk.

Case Study 2: The Brand Retailer Who Leveraged Long-Term Partnership for Flexibility

“Global Keepsakes Co.,” a growing brand retailer for travel-themed merchandise, wanted to introduce a new line of premium private label souvenirs but was wary of committing to large initial MOQs for an unproven product. Leveraging their established, five-year relationship with their China souvenir factory, they negotiated a crucial flexibility clause: a slightly higher per-unit cost for an initial lower-quantity trial run (below the standard MOQ of 1200 PCS, perhaps 500 units). The success of this trial allowed them to confidently commit to the factory’s standard bulk souvenir order MOQ for subsequent production, knowing the product would sell. Their manufacturing partnership with the resin souvenir manufacturer not only granted them this crucial flexibility but also provided invaluable feedback during the trial production phase, leading to minor design refinements.

Case Study 3: The Wholesaler Who Optimized Design for Scale

A large souvenir wholesaler identified that a particular customized souvenir design, a popular multi-part resin craft for souvenir, was proving disproportionately expensive due to intricate painting and assembly steps. By collaborating closely with their souvenir supplier China and engaging in a Design for Manufacturability (DFM) review, they made minor design modifications. These included simplifying a few color transitions and optimizing the assembly method, which significantly reduced labor time and material waste without compromising the aesthetic appeal. This smart design optimization led to a 10% reduction in production costs per unit. Applied across their large quantity souvenir production orders throughout the year, this seemingly small adjustment translated into hundreds of thousands in direct savings and vastly improved profit optimization.

The Bulk Buyer’s Blueprint: Mastering MOQs and Cost Efficiency in Souvenir Sourcing

Navigating the global souvenir market for bulk souvenir orders can feel like a high-stakes game. For tourism souvenir importers, wholesalers, and brand retailers, the twin challenges of Minimum Order Quantities (MOQs) and achieving true cost efficiency are constant concerns. It’s not just about finding a souvenir supplier China; it’s about finding the right one that understands your volume needs (1200+ PCS), optimizes your spend, and delivers without compromising on quality.

This blueprint is designed to arm you with the strategies and insights needed to master MOQs, unlock significant cost savings, and streamline your wholesale souvenir sourcing, ensuring every dollar invested delivers maximum value.

Demystifying MOQs: Understanding the Manufacturer’s Perspective

Minimum Order Quantities (MOQs) are often seen as a hurdle, but they’re a fundamental aspect of manufacturing economics. Understanding why they exist is the first step to mastering them. For bulk souvenir orders, MOQs are directly tied to production efficiency.

Why MOQs Exist: The Economics of Scale

Manufacturers, especially those specializing in customized souvenirs or specific materials like a resin souvenir manufacturer, set MOQs to cover their fixed costs associated with setting up a production run. These costs include:

- Tooling and Molds: Especially crucial for intricate resin craft for souvenir items or ceramic souvenir production, molds can be expensive to create. The MOQ helps amortize this cost across many units.

- Material Procurement: Suppliers offer better prices for raw materials (like specific grades of resin, wood, or metal) when purchased in larger volumes. MOQs ensure manufacturers can buy at these favorable rates, passing some of those savings onto you.

- Labor and Machine Setup: Each production run requires time for machine calibration, setup, and dedicated labor. Spreading these setup costs over a larger quantity makes each individual unit cheaper to produce, boosting the manufacturer’s efficiency.

- Waste Minimization: Larger production runs typically result in lower per-unit waste. The initial setup and calibration process might produce a few non-conforming units, but a higher volume means this initial waste is spread across more finished goods, reducing its impact on unit cost.

The MOQ Spectrum: From Flexible to Fixed

MOQs aren’t always a hard-and-fast number. They can vary significantly based on several factors, and recognizing this spectrum can give souvenir importers an edge in negotiation.

- Product Complexity: A simple, single-component resin fridge magnet manufacturer China might have a lower MOQ because their setup is quicker. In contrast, a factory producing highly intricate, multi-component iron art souvenir China items, or elaborate wooden souvenir China pieces, will likely have higher MOQs due to more complex tooling and specialized labor.

- Material Cost: If the raw material itself is expensive (e.g., precious metals, certain specialized resins, or rare woods), the MOQ might be lower in unit count but higher in total dollar value, as the manufacturer needs to recoup a significant material investment.

- Customization Level: Highly customized souvenirs that require unique molds, specific pantone color matching, or complex artwork often come with higher MOQs to justify the substantial upfront investment in custom setup and proofing. Standard designs allow for lower MOQs.

- Factory Size and Specialization: Larger China souvenir factory operations or those highly specialized in wholesale customized resin souvenir China might have higher MOQs. This is because their production lines are optimized for high-volume efficiency, and smaller runs disrupt this streamlined flow. Smaller, more flexible factories might offer lower MOQs but potentially at a higher per-unit cost.

Understanding this spectrum allows souvenir importers to better negotiate or align their purchasing strategies with manufacturer capabilities, ensuring realistic expectations from the outset.

Strategic Approaches to Mastering MOQs for Maximum Cost Efficiency

Navigating MOQs successfully means adopting smart purchasing strategies that benefit both you and your souvenir supplier China. It’s about more than just meeting the number; it’s about making the MOQ work for your bottom line.

Consolidation: The Power of Grouping Orders

One of the most effective ways for wholesale souvenir buyers to manage MOQs is through order consolidation. Instead of placing separate, smaller orders for different designs or variations, combine them into one larger order that collectively meets or exceeds the manufacturer’s MOQ.

- Multiple Designs within One Material/Factory: For example, if you need 5 different resin souvenir designs, and each individually has an MOQ of 300 PCS, many manufacturers will allow you to order 600 PCS of each design (total 3000 PCS) to meet a higher overall production run MOQ. This often translates into significantly better per-unit pricing than placing 5 separate 300-PC orders, as it saves the factory on multiple setups.

- Seasonal or Themed Bundles: Plan your purchasing strategically around seasonal events (like Christmas, Halloween, or summer travel peaks) or specific themes (e.g., coastal, adventure, historical). Placing a single bulk souvenir order for all holiday-themed travel retail souvenirs will likely yield superior pricing and logistical efficiency compared to piecemeal purchases throughout the year.

- Future Planning & Forecasting: This is crucial. By accurately forecasting your needs well in advance, you can commit to larger purchase orders less frequently. Anticipating future demand for popular best-selling travel gifts allows you to hit those MOQs consistently, securing better pricing and production slots. Implement robust inventory management to support this strategy.

Negotiation Tactics: Beyond the Sticker Price

Don’t treat MOQs as absolute, non-negotiable barriers. While they’re based on economic realities for the manufacturer, there’s often significant room for discussion, especially if you position yourself as a valuable, long-term partner.

- Building Long-Term Relationships: A souvenir supplier China is far more likely to be flexible with MOQs for a long-term, reliable partner. Demonstrating consistent order volumes, clear communication, and timely payments can open doors to reduced MOQs or more favorable pricing structures in the future. It’s an investment in a collaborative manufacturing partnership.

- Trial Orders and Smaller Runs: If you’re testing a new product idea or entering a new market, propose a trial run that’s slightly below the standard MOQ. Be prepared to pay a higher per-unit price for this initial flexibility. View this as a strategic investment in validating your product’s market viability before committing to a full large quantity souvenir production. Document the terms clearly.

- Paying a Premium for Lower MOQ: Sometimes, paying a slightly higher unit price for a smaller quantity makes perfect sense if it helps you manage inventory risk, especially for new or unproven customized souvenirs. Calculate carefully if the cost of holding excess, unsold inventory outweighs the initial higher per-unit price. This is a common strategy for brand retailers launching new lines.

- Leveraging Off-Peak Seasons: Manufacturers often have slower periods. They might be more flexible with MOQs or offer better pricing during these times, as they’re eager to keep production lines running and retain skilled labor. Inquire about their production calendar.

Design Optimization for Cost Savings

The very design of your tourism souvenir can have a profound impact on its cost, especially when scaled for bulk souvenir orders. Thinking about “design for manufacturability” (DFM) is key.

- Simplifying Complexities: Intricate details, numerous small components, or complex shapes often require more labor, specialized tooling, or slower machine cycles. Small, thoughtful design tweaks that simplify these complexities can significantly reduce production costs for a resin souvenir manufacturer or a wooden souvenir craftsman. Sometimes, less is more, both aesthetically and financially.

- Material Efficiency: Design your product to minimize material waste during cutting, molding, or assembly. For example, a resin fridge magnet manufacturer China can optimize mold layouts to reduce material scrap. Similarly, efficient cutting patterns for fabric travel retail souvenirs reduce waste.

- Standardization vs. Customization Balance: While customized souvenirs are essential for brand identity, identify elements that can be standardized (e.g., a common base for different figurine designs, a standard size for customized resin crafts) while maintaining uniqueness through variable elements like color, printing, or interchangeable parts. This approach is highly effective for wholesale customized resin souvenir China where a base mold can serve many different themes.

Unlocking True Cost Efficiency: Strategies Beyond Just Unit Price

Cost efficiency in souvenir sourcing for bulk buyers goes far beyond the per-unit price. It encompasses a holistic view of your entire investment, considering quality, logistics, inventory management, and potential hidden costs that can quickly erode profits.

The Hidden Costs of Poor Quality

We touched upon this earlier, but it bears repeating with emphasis: cheap isn’t always cost-efficient. Poor souvenir quality control can lead to devastating, often unseen, hidden costs that accumulate rapidly across bulk souvenir orders.

| Hidden Cost Factor | Direct & Indirect Impact on Bulk Souvenir Orders (1200+ PCS) | Mitigation Strategy with Robust QA |

| Defective Products | Waste of raw materials, wasted production time, loss of salable goods, potential need for emergency re-production (higher cost). | Pre-shipment inspection (PSI), Initial Production Check (IPC), and During Production Inspection (DPI) identify issues early, preventing mass defects and allowing for defect prevention. |

| Returns & Rework | Freight costs for returns, labor for inspection/repacking, potential discounts/refunds to dissatisfied retailers/consumers, handling fees. | Comprehensive in-line QA and stringent pre-shipment checks ensure products meet quality standards before leaving the factory, reducing the likelihood of returns. |

| Brand Damage & Lost Trust | Negative reviews, diminished customer loyalty, loss of future sales, reduced market share, difficulty attracting new retail partners. | Consistent quality standards, achieved through rigorous souvenir quality control, build a strong brand reputation and foster trust with both B2B and B2C customers. |

| Production Delays | Missed sales opportunities (especially seasonal), rush shipping fees, penalties from retailers for late delivery, inventory gaps. | Proactive process monitoring, early problem identification (IPC), and transparent communication with your souvenir supplier China prevent costly delays. |

| Excess Inventory | Warehousing costs, insurance, potential obsolescence if trends shift, capital tied up in unsold goods. | Accurate forecasting combined with flexible MOQ negotiations and efficient production lead times reduce the need for excessive buffer stock. |

Export to Sheets

This table unequivocally highlights that investing in a robust quality assurance global souvenir supply chain isn’t an expense; it’s a critical, proactive investment in profit optimization and supply chain risk management. It shifts your focus from firefighting to strategic growth.

Optimizing Logistics and Shipping for Wholesale Souvenirs

Logistics can often be a significant, sometimes overlooked, portion of your total landed cost. Efficient shipping for bulk souvenir orders is crucial for maintaining cost efficiency.

- Consolidate Shipments Strategically: If you’re sourcing different types of wholesale souvenirs from multiple souvenir suppliers China within the same region, explore consolidating them into one larger container. This can significantly reduce per-CBM (cubic meter) freight rates compared to multiple smaller shipments.

- Choose the Right Incoterms: Understand the implications of different Incoterms (e.g., FOB, EXW, CIF) and choose the one that offers the best balance of cost, risk, and control for your specific business model. For many tourism souvenir importers, FOB (Free On Board) is preferred as it gives them control over the freight forwarder and international shipping costs.

- Strategic Warehousing and Distribution: Optimize your warehousing strategy to minimize storage costs and efficiently manage your wholesale souvenir inventory. Consider direct-to-retailer shipping where feasible to reduce double-handling.

- Partner with Professional Freight Forwarders: Engage experienced freight forwarders who specialize in souvenir import logistics. They can navigate complex customs clearance procedures, advise on optimal shipping routes, and often secure better rates, preventing costly delays and unexpected charges.

The Value of a Long-Term Manufacturing Partnership

Building a strong, long-term manufacturing partnership with a China souvenir factory can lead to profound and sustained cost efficiencies, well beyond what short-term, transactional relationships can offer.

- Preferred Pricing and Flexibility: Loyal customers often receive better pricing structures, more flexible MOQs (especially during off-peak seasons), and priority in production scheduling. This can be invaluable during peak seasons or when urgent bulk souvenir orders arise.

- Improved Communication and Understanding: A long-standing relationship fosters a deeper understanding of your specific needs, brand standards, and evolving quality expectations. This leads to fewer miscommunications, fewer errors, and ultimately more efficient and accurate production of customized souvenirs.

- Innovation and Product Development Support: A trusted partner might offer invaluable insights into new materials, more efficient production techniques, or cost-saving design tweaks (Design for Manufacturability – DFM) during souvenir product development. This collaborative approach helps you stay ahead in the global souvenir market. For example, a specialized resin souvenir manufacturer might introduce you to a new, more durable, or cost-effective resin compound.

Case Studies: Real-World Wins in MOQ & Cost Mastery

Understanding concepts is one thing; seeing them in action provides invaluable context. Here are some scenarios showcasing how strategic MOQ management and holistic cost efficiency have paid off for tourism souvenir importers and brand retailers.

Case Study 1: The Small Importer Who Mastered Consolidation

“Voyage Vault Souvenirs,” a boutique tourism souvenir importer, initially struggled with high per-unit costs due to placing multiple small, fragmented orders for different designs from various factories. Their individual orders often fell below preferred MOQs, leading to higher prices. By strategically consolidating their wholesale souvenir gifts across themes (e.g., combining city-specific resin fridge magnets, wooden keychains, and small ceramic mugs into one larger order) with a single, versatile souvenir supplier China capable of multi-product runs, they dramatically improved their leverage. This led to a negotiated reduction in overall MOQs across product lines and, crucially, a decrease in their average per-unit cost by a remarkable 15% over two fiscal quarters. This allowed them to diversify their offerings for travel retail souvenirs without incurring excessive inventory risk.

Case Study 2: The Brand Retailer Who Leveraged Long-Term Partnership for Flexibility

“Global Keepsakes Co.,” a growing brand retailer for travel-themed merchandise, wanted to introduce a new line of premium private label souvenirs but was wary of committing to large initial MOQs for an unproven product. Leveraging their established, five-year relationship with their China souvenir factory, they negotiated a crucial flexibility clause: a slightly higher per-unit cost for an initial lower-quantity trial run (below the standard MOQ of 1200 PCS, perhaps 500 units). The success of this trial allowed them to confidently commit to the factory’s standard bulk souvenir order MOQ for subsequent production, knowing the product would sell. Their manufacturing partnership with the resin souvenir manufacturer not only granted them this crucial flexibility but also provided invaluable feedback during the trial production phase, leading to minor design refinements.

Case Study 3: The Wholesaler Who Optimized Design for Scale

A large souvenir wholesaler identified that a particular customized souvenir design, a popular multi-part resin craft for souvenir, was proving disproportionately expensive due to intricate painting and assembly steps. By collaborating closely with their souvenir supplier China and engaging in a Design for Manufacturability (DFM) review, they made minor design modifications. These included simplifying a few color transitions and optimizing the assembly method, which significantly reduced labor time and material waste without compromising the aesthetic appeal. This smart design optimization led to a 10% reduction in production costs per unit. Applied across their large quantity souvenir production orders throughout the year, this seemingly small adjustment translated into hundreds of thousands in direct savings and vastly improved profit optimization.

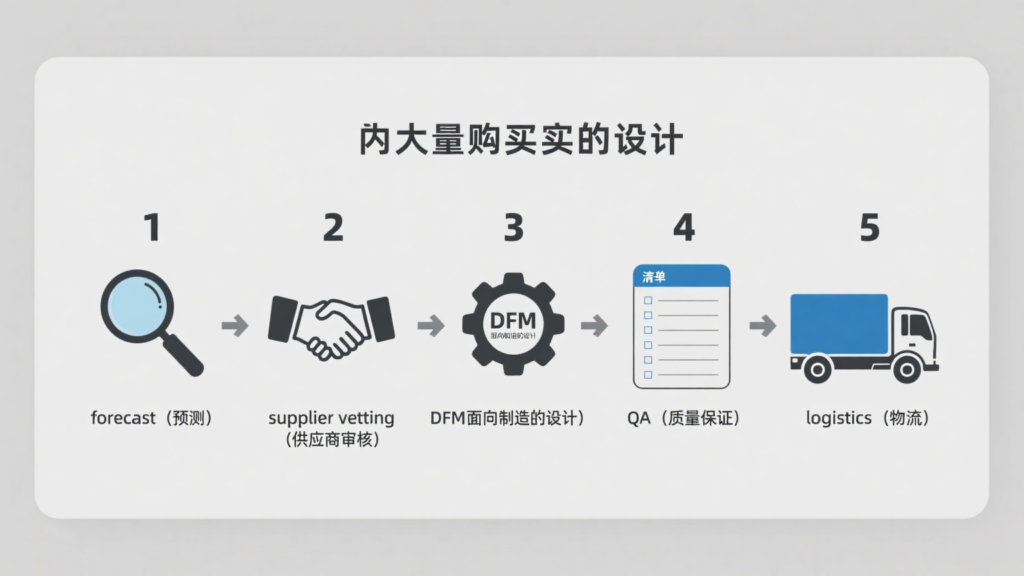

Blueprinting Your Success: Actionable Steps for Bulk Buyers

Now that we’ve explored the strategies, let’s distill them into actionable steps for tourism souvenir importers, wholesalers, and brand retailers to master MOQs and achieve peak cost efficiency.

Step 1: Deep Dive into Your Demand Forecast

Accurate and consistent forecasting is your first and most powerful weapon against MOQ challenges and inventory risks. Understand your historical sales data thoroughly, meticulously anticipate seasonal peaks and troughs, and analyze current and emerging souvenir market trends for best-selling travel gifts. A clear, data-backed forecast empowers you to commit to larger MOQs with confidence, unlocking better pricing on bulk souvenir orders and avoiding costly overstock or stockouts. Invest in robust forecasting tools and methodologies.

Step 2: Strategic Supplier Selection and Vetting

Don’t just pick the cheapest quote you find online. Your choice of souvenir supplier China is a strategic decision. Look for a partner that demonstrates flexibility, transparency, and, most importantly, a strong, demonstrable commitment to quality assurance global souvenir supply chain. Conduct thorough factory audits (either in-person or via reputable third parties), check their capabilities for large scale manufacturing of your specific product type, and be explicit about your MOQ requirements. This is where your investment in vendor management truly pays off, establishing a relationship built on trust and mutual understanding.

Step 3: Embrace Design for Manufacturability (DFM)

Collaborate intimately with your manufacturer during the design and prototyping phase. A reputable resin souvenir manufacturer or ceramic souvenir factory China can provide invaluable insights on how to optimize your customized souvenirs for efficient production. This involves simplifying complex geometries, standardizing components where possible, and selecting materials that lend themselves to efficient mass production. DFM efforts directly reduce waste, labor time, and ultimately lower per-unit costs for bulk souvenir orders.

Step 4: Implement a Multi-Layered Quality Assurance Strategy

Never, ever rely solely on a single final inspection. Adopt a comprehensive quality assurance global souvenir supply chain approach that incorporates Incoming Quality Control (IQC) for raw materials, Initial Production Checks (IPC), During Production Inspections (DPI), and a stringent Pre-Shipment Inspection (PSI). This proactive, multi-layered defect prevention strategy is your best friend for large quantity souvenir production and ensures that every single one of your travel retail souvenirs meets your exacting standards before it ever leaves the factory.

Step 5: Optimize Your Logistics and Supply Chain Management

Your supply chain is a critical cost center. Work closely with experienced freight forwarders who deeply understand souvenir import logistics and can provide tailored solutions. Explore options for shipment consolidation (combining goods from multiple factories into one container) and choose Incoterms that benefit your cost and risk profile. Efficient supply chain risk management goes hand-in-hand with cost efficiency, minimizing unexpected delays, damages, and detention fees.

Conclusion: Unleashing the Full Potential of Your Souvenir Sourcing

Mastering MOQs and achieving true cost efficiency in souvenir sourcing is an ongoing journey, but it’s one that yields significant rewards. For tourism souvenir importers, wholesalers, and brand retailers dealing in bulk souvenir orders, this blueprint provides the strategic framework to navigate complexities, mitigate risks, and unlock substantial savings.

By adopting a proactive approach to MOQs, focusing on holistic cost efficiency, and critically, by partnering with a knowledgeable and reliable souvenir supplier China like Craft Manufacturer China, you can transform these traditional manufacturing hurdles into powerful competitive advantages. Our expertise in customized souvenirs, diverse material capabilities (including our specialization as a resin fridge magnet manufacturer China), and unwavering commitment to quality assurance empower you to build a profitable, efficient, and resilient global souvenir supply chain. Let us help you turn your wholesale souvenir aspirations into market-dominating realities.

Frequently Asked Questions (FAQs)

- Q1: What exactly are MOQs, and why do manufacturers set them for bulk souvenir orders?

- A: MOQs (Minimum Order Quantities) are the fewest units a manufacturer is willing to produce in a single run. They exist primarily to cover fixed costs like tooling, material procurement at wholesale rates, and machine setup, making large quantity souvenir production economically viable for the souvenir supplier China.

- Q2: How can tourism souvenir importers reduce costs if they can’t meet a high MOQ for a new product?

- A: Consider consolidating multiple product designs into one larger order to meet a combined MOQ, negotiating a trial run with a slightly higher per-unit cost, or paying a small premium for a lower MOQ to test the market for your customized souvenirs. Building a strong relationship with your souvenir supplier China can also lead to more flexibility.

- Q3: What are the biggest hidden costs that wholesale souvenir buyers should be aware of beyond the per-unit price?

- A: Hidden costs include losses from defective products, rework/return shipping, production delays, and damage to brand reputation due to poor quality. Robust souvenir quality control and efficient souvenir import logistics are essential to mitigate these and ensure profit optimization.

- Q4: How does Craft Manufacturer China help clients manage MOQs for wholesale customized resin souvenir China orders?

- A: As a dedicated resin fridge magnet manufacturer China and a comprehensive souvenir supplier China, we offer flexible solutions. We optimize production processes for various resin craft for souvenir items, advise on design modifications for cost-efficiency, and work with clients to consolidate orders, helping them meet bulk souvenir orders effectively while maintaining high standards of quality assurance.

- Q5: What role does quality assurance play in achieving cost efficiency for bulk souvenir orders?

- A: Comprehensive quality assurance global souvenir supply chain significantly reduces defects, minimizes costly rework and returns, prevents production delays, and protects your brand reputation. This proactive defect prevention is a direct investment in long-term cost efficiency and profit optimization for your wholesale souvenirs.

- Q6: What’s the typical lead time for implementing comprehensive QA processes on large wholesale customized resin souvenir China orders?

- A: While the QA process is integrated into the production timeline, it’s crucial to factor in dedicated time for pre-production sample approvals (which can take 1-2 weeks depending on complexity and revisions) and subsequent inspection windows throughout manufacturing. A dedicated resin souvenir manufacturer like us will typically have these QA milestones built into their overall large scale manufacturing production schedule.

- Q7: Beyond pricing, what are the long-term benefits of a strong manufacturing partnership with a China souvenir factory for bulk buyers?

- A: A strong manufacturing partnership leads to preferred pricing, increased flexibility on MOQs, improved communication, fewer errors due to deeper mutual understanding, and invaluable support in souvenir product development and innovation. It’s a strategic asset for any tourism souvenir importer or brand retailer.

- Resin vs. Ceramic: A Data-Driven B2B Comparison for High-Volume Souvenir Orders - February 4, 2026

- AQL 2.5 vs. 4.0: Defining Acceptable Defect Thresholds for Mass-Produced Tourist Magnets - January 28, 2026

- The Importer’s Guide to Total Landed Cost (TLC): Calculating the Real Price of Resin Souvenirs from Quanzhou - January 21, 2026