For a tourism souvenir importer or a large-scale wholesaler, the moment of truth arrives when the container door swings open at your warehouse. You’ve invested months in souvenir product development and thousands of dollars in bulk souvenir orders. But as you pull the first few master cartons of custom fridge magnets, you notice a problem: five out of the first fifty have slight paint bleeds, and one has a magnet that has completely detached from the resin base.

Is this a disaster? Or is it a statistically “acceptable” part of high-volume China souvenir factory production?

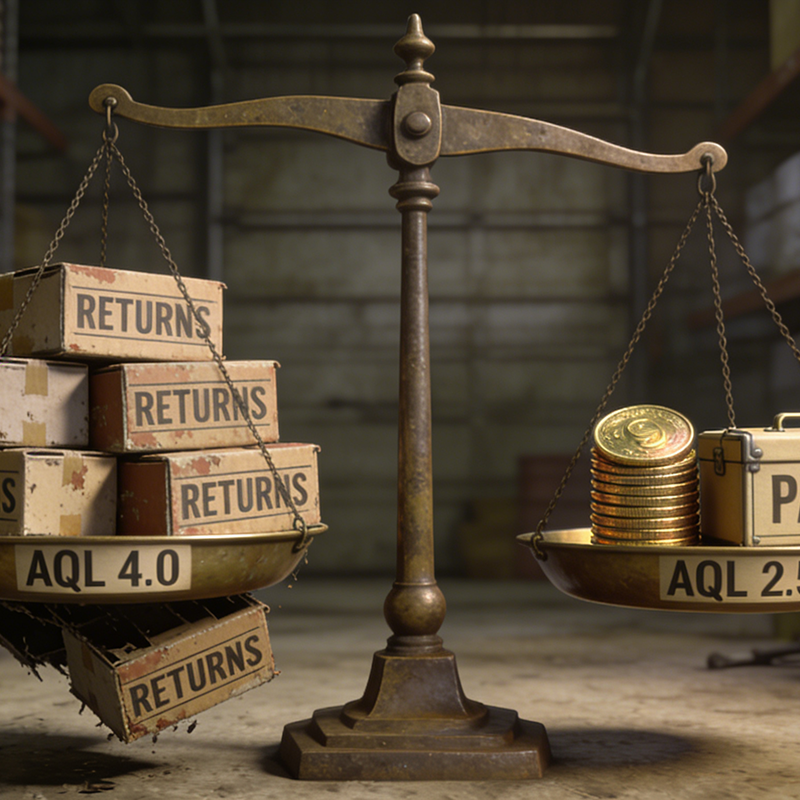

The answer lies in three letters: AQL (Acceptable Quality Level). Specifically, the debate between AQL 2.5 and AQL 4.0. Understanding these thresholds isn’t just a technicality for the QC team; it is a fundamental pillar of profit optimization and landed cost analysis. If your quality standards are too loose, your brand reputation suffers; if they are too tight, your unit costs skyrocket.

In this comprehensive guide, we will break down how to define defect thresholds specifically for mass-produced magnets, ensuring your manufacturing partnership remains both profitable and high-quality.

The Competitor Landscape: What’s Being Said (and What’s Missing)

Most “Sourcing 101” blogs provide a generic overview of AQL tables. Their outlines usually look like this:

- What is AQL? A basic definition of the ANSI/ASQ Z1.4 standard.

- The AQL Table: A confusing screenshot of the “magic” charts.

- Major vs. Minor: A generic list of defects (e.g., “it’s broken” vs. “it’s dirty”).

- Why use it? To save time on inspections.

The “Skyscraper” Expansion:

While the basics are fine, they fail the tourism souvenir importer because magnets have unique physical properties and retail expectations. A generic AQL guide doesn’t tell you how to classify a “weak magnetic pull” or a “resin odor.” We are expanding the topic to include:

- Souvenir-Specific Defect Classification: Tailoring thresholds to resin, PVC, and metal magnets.

- The ROI of AQL: How choosing 2.5 over 4.0 affects your landed cost analysis.

- Inspection Level G-II vs. S-3: Choosing the right sample size for high-volume souvenir runs.

- Contractual Enforcement: How to bake these standards into your manufacturing partnership.

Defining the “Souvenir Trinity”: Critical, Major, and Minor Defects

Before choosing between 2.5 and 4.0, you must define what a defect actually is in the context of custom souvenirs. At a professional China souvenir factory, defects are categorized into three tiers.

1. Critical Defects (AQL 0)

These are non-negotiable. If a single critical defect is found, the entire lot is usually rejected. For magnets, these include:

- Safety Hazards: Sharp metal edges, toxic lead paint (violating CPSIA/EU standards), or small magnets that are easily swallowed (choking hazards).

- Legal Non-compliance: Missing “Made in China” country-of-origin markings or incorrect licensing/trademark labels for private label souvenirs.

2. Major Defects (The AQL 2.5 Target)

A major defect makes the product unsellable to a discerning tourist or leads to a retail return. In resin souvenir manufacturer terms, these are:

- Functional Failure: The magnet is missing or the adhesive has failed, causing the magnet to fall off.

- Structural Damage: Large cracks in the resin, broken limbs on 3D characters, or deep scratches on metal plates.

- Severe Aesthetic Issues: Wrong colors (e.g., the Eiffel Tower is green instead of bronze) or missing text in the destination name.

3. Minor Defects (The AQL 4.0 Target)

A minor defect is a departure from the specification that the average tourist might overlook, but a brand retailer would still prefer to avoid:

- Slight Paint Bleed: A tiny speck of blue paint on a white background.

- Micro-Bubbles: Small air pockets in the resin cast that don’t affect structural integrity.

- Packaging Scuffs: Minor wrinkles on the individual polybag that don’t damage the magnet inside.

AQL 2.5 vs. 4.0: The Statistical Battleground

When you set an AQL level, you are telling the souvenir quality control team how many “Major” and “Minor” defects are allowed in a randomly selected sample before the whole batch is rejected.

The AQL 2.5 Standard (High Quality)

This is the industry standard for brand retailers and mid-to-high-end gift shops. It means that, statistically, you are willing to accept a batch where fewer than 2.5% of the items have “Major” defects. For a batch of 10,000 magnets, using a standard G-II inspection level, the inspector might check 200 units. If they find more than 10 major defects, the batch fails.

The AQL 4.0 Standard (Budget/Volume)

This is common for “dollar store” items or low-margin wholesale souvenirs. It allows for a higher defect rate (up to 4%). It is cheaper for the factory because they don’t have to spend as much time on manual “touch-ups” and sorting, but it increases the risk of “buyer’s remorse” at the retail level.

Data Comparison: Impact on a 10,000 Unit Magnet Order

To truly understand profit optimization, look at how these standards play out in a real-world landed cost analysis.

| Feature | Standard AQL (2.5 / 4.0) | Tight AQL (1.5 / 2.5) | Impact on Total Landed Cost |

| Inspection Level | G-II (Standard) | G-II (Standard) | Higher rigor = more time. |

| Sample Size (of 10k) | 200 – 315 units | 200 – 315 units | No change in inspection cost. |

| Major Defect Limit | 10 units (2.5) | 7 units (1.5) | Tighter limits force factory precision. |

| Minor Defect Limit | 14 units (4.0) | 10 units (2.5) | Reduces “unprofessional” specks/bleeds. |

| Unit Price Impact | Baseline ($0.65) | +3% to 5% ($0.68) | Higher price covers factory “waste.” |

| Estimated Return Rate | 2% to 4% | <1% | Lower returns = Higher Net Profit. |

Note: In the world of mass-produced tourist magnets, the “Accept” and “Reject” numbers are determined by the ISO 2859-1 tables. The numbers above are illustrative of the threshold differences.

Choosing the Right Level for Your Souvenir Category

One size does not fit all in the global souvenir supply chain. Your AQL strategy should change based on the material and the target price point of your custom souvenirs.

For Resin Magnets (Resin Souvenir Manufacturer)

Resin is brittle and hand-painted. Because of the manual labor involved, “Minor” defects (paint slips) are common.

- Recommendation: AQL 2.5 for Major / 4.0 for Minor. This balances the reality of hand-crafting with the need for a professional look.

For PVC/Rubber Magnets (High Precision)

PVC magnets are made using injection molds or dispensing machines. They are very consistent.

- Recommendation: AQL 1.5 for Major / 2.5 for Minor. Because the process is automated, there is no excuse for high defect rates.

For Metal/Enamel Magnets (Luxury Souvenirs)

Metal magnets often command a higher retail price at airports or museums.

- Recommendation: AQL 1.0 for Major / 2.5 for Minor. Tourists paying $12 for a magnet expect perfection.

How to Negotiate AQL with a China Souvenir Factory

A common mistake for a tourism souvenir importer is assuming the factory knows your standards. If you don’t specify AQL in your Purchase Order (PO), the factory will default to their own internal standard—which is usually “whatever we can get away with.”

1. The “Golden Sample” Reference

The AQL standard is useless without a “Golden Sample.” This is the approved PPS (Pre-Production Sample). Your contract should state: “Any deviation from the Golden Sample color, weight, or finish is a Major Defect under AQL 2.5.”

2. The Inspection Clause

Your contract should state: “Third-party inspection will be performed at the factory prior to shipment. If the lot fails AQL 2.5/4.0 standards, the factory is responsible for 100% sorting and the cost of the re-inspection.” This is the ultimate lever for profit optimization.

3. Material-Specific Clauses

For magnets, add a specific “Pull Strength” test to your AQL checklist. If a magnet can’t hold three sheets of A4 paper on a fridge, it is a Major Defect.

Calculating the ROI: Is 2.5 Worth the Extra Cost?

Many wholesalers worry that demanding AQL 2.5 will make their wholesale pricing uncompetitive. However, let’s look at the hidden costs of AQL 4.0:

- Administrative Overhead: The time your team spends handling emails about 500 broken magnets.

- Reverse Logistics: The cost of shipping replacements to a frustrated brand retailer.

- Opportunity Cost: The retail shelf space occupied by a “uglier” magnet that takes longer to sell.

When you perform a true landed cost analysis, the 3% premium you pay for a tighter AQL is almost always recovered through higher sell-through rates and zero-defect reputations.

Conclusion: Setting the Standard for Your Brand

In the world of mass-produced tourist magnets, quality is not an accident; it is a statistical choice. By defining your AQL 2.5 vs. 4.0 thresholds clearly, you empower your China souvenir factory to meet your expectations and protect your margins.

Whether you are building a line of private label souvenirs for a national park or managing bulk souvenir orders for an international airport, the AQL standard is your shield against supply chain chaos. Don’t leave your quality to chance—make it a part of your mathematical blueprint for success.

Is your current supplier meeting your quality expectations? At Craftmgf.com, we specialize in high-precision manufacturing with transparent AQL reporting. Contact us today for a consultation on your next bulk souvenir order and let us help you optimize your quality-to-cost ratio.

- AQL 2.5 vs. 4.0: Defining Acceptable Defect Thresholds for Mass-Produced Tourist Magnets - January 28, 2026

- The Importer’s Guide to Total Landed Cost (TLC): Calculating the Real Price of Resin Souvenirs from Quanzhou - January 21, 2026

- Eco-Friendly Manufacturing Practices: Our Commitment to Biodegradable & Low-VOC Production - January 14, 2026