For every tourism souvenir importer, wholesaler, and brand retailer, the successful management of the annual supply chain cycle hinges on one critical, often opaque metric: the manufacturing lead time.

In the global souvenir supply chain, your lead time is not just a number on a calendar; it is the ultimate determinant of your market readiness, inventory levels, and—most importantly—your profit optimization. Mismanaging it, especially around the major Chinese holidays like Chinese New Year (CNY) and Golden Week, can lead to devastating stock-outs, air freight emergencies, and lost revenue.

While many China souvenir factory suppliers simply quote a general “30-45 days,” that generalization is a recipe for disaster during peak season. A true manufacturing partnership provides transparency, predictability, and a shared strategy for navigating these bottleneck periods.

This definitive guide, written by your SEO expert team, is designed to empower you, our high-value clients, to move from reacting to schedules to proactively dictating them. We will decode the factors influencing souvenir production timelines, provide a strategic calendar for peak season, and demonstrate how advanced planning can be your single greatest competitive advantage in securing your bulk souvenir orders on time.

The Hidden Variables: What Really Drives Your Manufacturing Lead Time

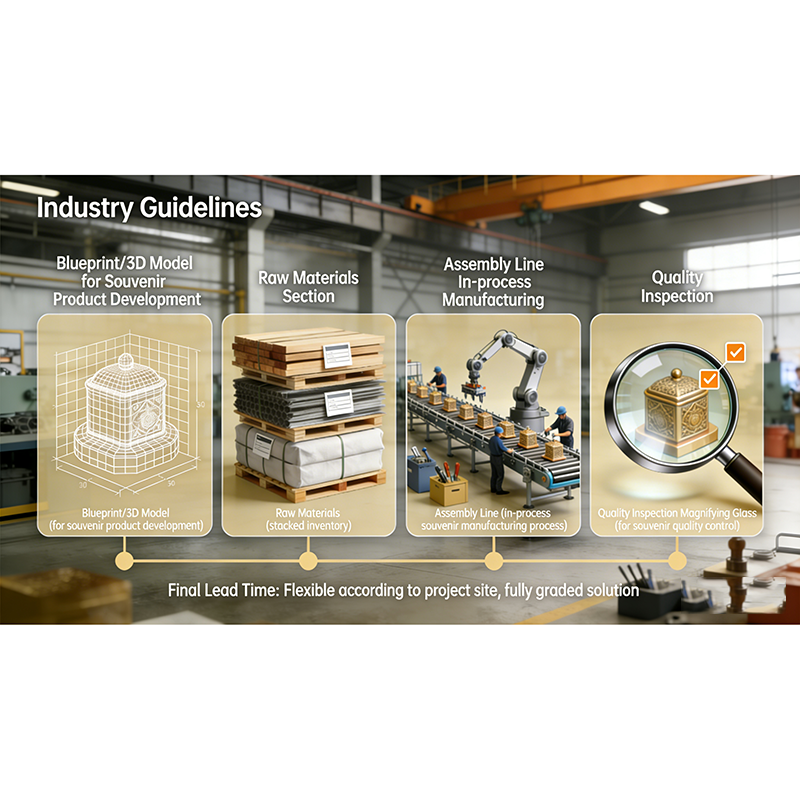

To accurately predict your delivery date, you must first understand that the quoted lead time is the sum of several distinct, time-consuming stages—not just the production line. The typical lead time for custom souvenirs or private label souvenirs is broken down by the following critical stages:

1. Souvenir Product Development & Sampling (The Longest Variable)

This phase, crucial for custom souvenirs, often consumes more time than the actual production. Competitors often quote the lead time after sample approval, but savvy tourism souvenir importers must factor this in.

- Design and Prototyping: For a complex resin souvenir manufacturer project, initial 3D modeling and mold development can take 10-15 days.

- Physical Sampling: Creating the first physical Pre-Production Sample (PPS), shipping it, and waiting for your approval can add another 10-15 days, depending heavily on courier speed and your internal approval process. This is a non-negotiable stage for ensuring souvenir quality control.

2. Raw Material Sourcing and Preparation

The moment your sample is approved, the factory begins sourcing. This is a major bottleneck during peak season.

- Specialized Material Sourcing: If your bulk souvenir orders require specialized materials (e.g., specific grades of steel for iron art souvenir China, or certified FSC-certified wooden souvenir China), the supplier’s lead time for these materials can be 7-10 days, or longer if imported.

- Pre-Processing: Materials like wood, clay for ceramic souvenir production, or certain chemicals need time for preparation, curing, or inspection before the main souvenir manufacturing process can begin.

3. Core Souvenir Manufacturing Process (The Quoted Time)

This is the time most suppliers quote, covering molding, assembly, painting, and packaging. The actual duration depends on the volume and complexity of your souvenir crafts.

- Complexity Factor: A high-detail figurine from a resin souvenir manufacturer requires multiple steps (molding, de-molding, curing, sanding, painting), significantly extending the time compared to a simple, unadorned wholesale souvenirs product.

- Capacity Factor: During peak months, a China souvenir factory with limited capacity may push your order into an already congested queue, adding buffer time. This is where a strong manufacturing partnership guarantees your slot.

4. Souvenir Quality Control and Packaging (The Final Hurdle)

This critical stage, often rushed by less professional suppliers, is vital for your brand reputation.

- In-house QC: Final inspection and testing of the finished custom souvenirs can take 3-5 days for a major large quantity souvenir production run.

- Custom Packaging: If your private label souvenirs require specific, bespoke packaging (custom boxes, clamshells, inserts), the packaging production lead time itself must be factored in, as this is often outsourced to specialized firms.

The Peak Season Disruptors: CNY and Golden Week

These two annual holidays are not just breaks; they are massive logistical disruptions that must be treated as immovable deadlines. Failing to factor these into your souvenir production timelines guarantees delays and forces expensive air freight.

Chinese New Year (CNY): The 60-Day Disruption

CNY is the single largest annual hurdle in the global souvenir supply chain. The effective disruption is not the 7-10 day official holiday, but a 6-to-8-week window of chaos.

- Pre-CNY Rush (4-6 Weeks Out): Every tourism souvenir importer is rushing to get their bulk souvenir orders shipped before the factory closure and the final port cutoff dates. Prices for souvenir import logistics (ocean freight) spike, and booking space becomes challenging.

- Factory Closure (2-3 Weeks): Workers return home, and the entire China souvenir factory shuts down. No production, no communication, no loading.

- Post-CNY Ramp-Up (2-4 Weeks After): Production does not immediately resume at 100%. Factories deal with labor turnover and machine maintenance. Production capacity slowly ramps up, meaning the first few orders placed after CNY may still face significant delays. Manufacturing lead time can be heavily inflated in this window.

Golden Week (Early October): The Mini-CNY

While shorter (7 days), Golden Week still requires advance planning, particularly for wholesalers targeting holiday retail seasons (Thanksgiving, Christmas). The port congestion and pre-holiday rush can add 10-15 days to your normal souvenir import logistics timeline.

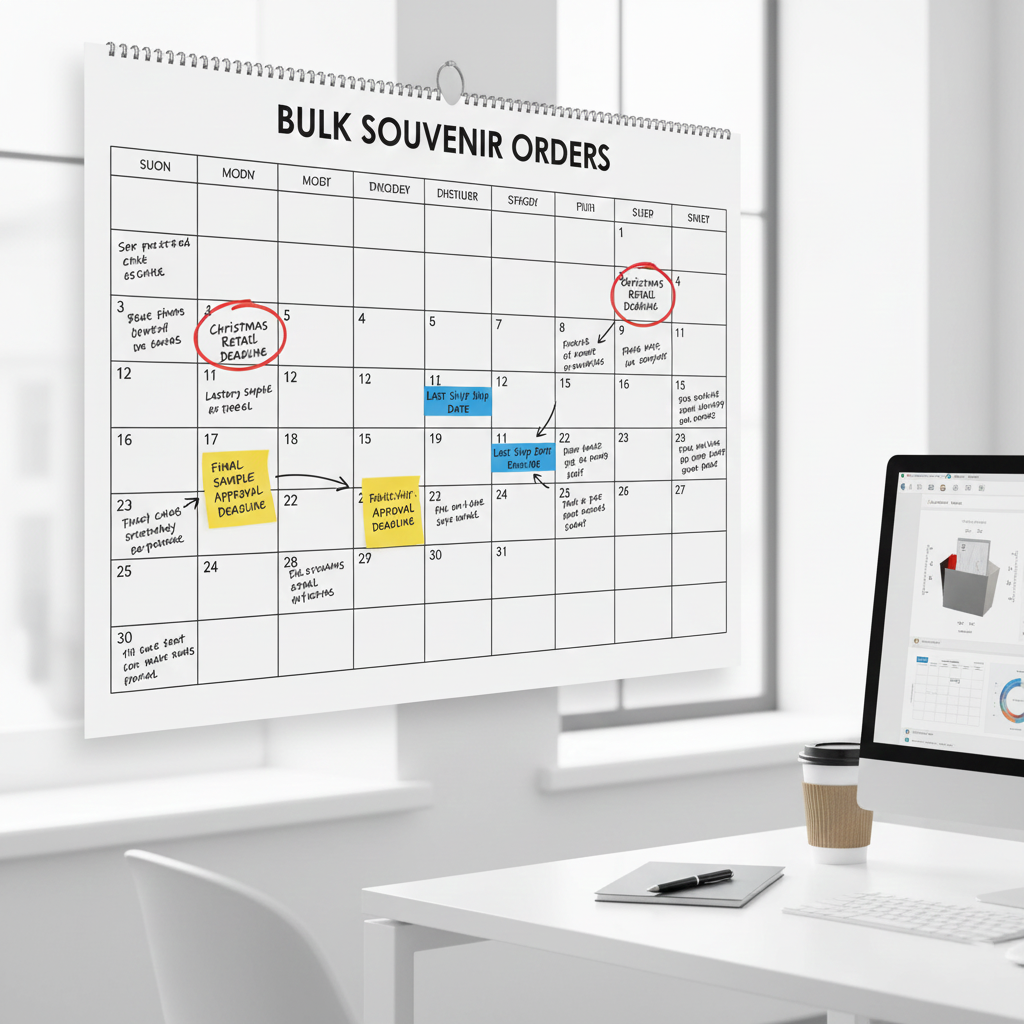

The Strategic Calendar: Predicting Your Production Slots

To ensure your large quantity souvenir production avoids these holiday bottlenecks, brand retailers and wholesalers must work backward from their In-Warehouse date. Here is an illustrative, optimized production calendar based on a standard 45-day manufacturing lead time for a complex custom souvenirs project, highlighting the critical deadlines:

| Key Retail Date Target | Last Safe In-Warehouse Date | Required Factory Ship Date | Final Sample Approval Deadline | Initial Order Placement Deadline |

| Christmas Season (Early Nov) | October 20 | September 5 | August 1 | July 15 |

| Golden Week Bypass (Late Sept) | September 15 | August 1 | July 1 | June 15 |

| CNY Pre-Shipment (Late Jan) | January 15 | December 1 | November 1 | October 15 |

Note: This table assumes 35-45 days for manufacturing and 30-45 days for souvenir import logistics (ocean freight). Missing the final approval deadline (bolded) for the CNY pre-shipment may necessitate highly expensive air freight to avoid stock-outs.

This data is crucial for profit optimization. Missing the December 1 shipment date means your only option is costly air freight, which can easily add $1.00 – $3.00 per unit to your wholesale souvenirs cost, erasing your entire profit margin.

The Proactive Blueprint: Strategies for Manufacturing Lead Time Control

A professional manufacturing partnership empowers you with tools to minimize risk and manage these schedules. These are the strategies we use at Craftmgf.com to guarantee timely bulk souvenir orders.

1. Advance Capacity Reservation (ACR)

For major wholesalers with predictable annual volume, we recommend ACR. This involves placing a strategic deposit or framework order with the China souvenir factory months in advance to reserve your slot on the production calendar, particularly for your large quantity souvenir production runs that require complex souvenir product development. This ensures that when your final design is ready, your order jumps the queue.

2. Strategic MOQ Negotiation and Bulk Sourcing

Lead times can be dramatically reduced by placing larger, more strategic bulk souvenir orders.

- Raw Material Pre-Order: By consolidating your SKUs and placing a larger annual order, the China souvenir factory can order raw materials like resin or wood in advance. This bypasses the 7-10 day material sourcing lead time for your specific order, speeding up the overall souvenir manufacturing process.

- Tooling Investment: Invest in durable, high-capacity tooling upfront. A higher-quality mold, especially for a resin souvenir manufacturer, lasts longer and allows for faster, continuous production runs, reducing the overall time needed to fulfill your wholesale souvenirs.

3. Leveraging a Material-Specific Manufacturing Partnership

Your material choice directly impacts the lead time. A specialized resin souvenir manufacturer that controls all stages in-house (molding, painting, assembly) will have a more predictable manufacturing lead time than a general trading company that outsources three different stages to three different factories.

- Example: A ceramic souvenir production run often requires long, non-negotiable kiln times and cool-down periods. By contrast, processes used by an iron art souvenir China expert, or the rapid-curing process used by a resin souvenir manufacturer, can offer greater schedule flexibility.

4. Mastering Souvenir Import Logistics Through Planning

The factory ship date is not your delivery date. The most reliable tourism souvenir importers book their freight space before the goods are finished.

- Pre-Booking Freight: Book your container space 4-6 weeks out, especially before CNY. This protects you from price spikes and ensures you get space on the final vessels before the port cutoffs. A quality manufacturing partnership should provide you with accurate CBM (Cubic Meter) estimates immediately upon PPS approval to enable this.

- Simplified Packaging: Use standard, pre-approved packaging and labeling for your private label souvenirs. Waiting for custom, complex packaging production can easily add 10 days to the schedule and delay your entire bulk souvenir order.

The Craftmgf.com Commitment: Transparency in the Global Souvenir Supply Chain

At Craftmgf.com, we view lead time management as a core responsibility of our manufacturing partnership. We provide not just a quote, but a transparent breakdown of your souvenir production timelines, detailing every step from souvenir product development to souvenir quality control.

We understand that for wholesalers and brand retailers, accurate scheduling is essential for profit optimization. We use a proprietary scheduling system that accounts for raw material availability, labor utilization during peak periods, and real-time souvenir import logistics data to give you the most reliable delivery estimate possible.

Don’t let the annual rush of CNY and Golden Week dictate your business success. Choose a China souvenir factory that provides the predictability and strategic planning required to maintain control over your global souvenir supply chain and ensure your custom souvenirs arrive on time, every time.

Ready to gain control over your production schedules? Contact Craftmgf.com today to discuss your next bulk souvenir order and receive a detailed, stage-by-stage manufacturing lead time analysis.

- AQL 2.5 vs. 4.0: Defining Acceptable Defect Thresholds for Mass-Produced Tourist Magnets - January 28, 2026

- The Importer’s Guide to Total Landed Cost (TLC): Calculating the Real Price of Resin Souvenirs from Quanzhou - January 21, 2026

- Eco-Friendly Manufacturing Practices: Our Commitment to Biodegradable & Low-VOC Production - January 14, 2026