The global souvenir market is a realm of vibrant cultural exchange and significant business opportunity. But for international souvenir importers, wholesalers, and brand retailers dealing in bulk souvenirs (especially those large MOQs of 1200+ PCS), one challenge looms large: Quality Assurance Beyond Borders. You know the drill – a defect in a single unit might be manageable, but multiply that by thousands, and you’re looking at damaged reputations, financial losses, and logistical nightmares.

This article isn’t just about what quality assurance is; it’s about building a fortress of excellence around your global souvenir supply chain. We’ll delve deep into the strategic importance of robust QA, dissecting how top players ensure perfection, and ultimately, how partnering with the right souvenir suppliers China can safeguard your brand and bottom line.

The Imperative of Quality: Why It’s More Critical Than Ever for Bulk Buyers

In the fiercely competitive landscape of international trade, quality isn’t just a buzzword; it’s the bedrock of your business. For souvenir importers, wholesalers, and brand retailers, especially when placing bulk orders with MOQs exceeding 1200 PCS, quality assurance (QA) isn’t merely an option – it’s a non-negotiable strategic imperative. Your brand’s reputation, customer satisfaction, and ultimately, your profitability, hinge on the consistent quality of every single customized souvenir or wholesale souvenir gift you bring to market.

The High Stakes of Large-Volume Sourcing

When you’re dealing with thousands of units, even a small defect rate can translate into massive losses. Imagine a 3% defect rate on an order of 5,000 resin fridge magnets – that’s 150 unusable units, wasted production costs, potential chargebacks, and unhappy retail partners. This exponential risk necessitates a proactive, ironclad QA strategy. It’s about preventing problems long before they ship, not just fixing them when they arrive.

Protecting Your Brand and Customer Trust

Your brand is your most valuable asset. A single batch of subpar travel souvenirs can quickly erode customer trust, lead to negative reviews, and harm your reputation in the marketplace. Customers expect consistent quality, especially from established brands. Effective souvenir quality control ensures that every product reaching your shelves meets or exceeds expectations, fostering loyalty and positive word-of-mouth. This is especially true for private label souvenirs, where your brand name is directly on the product. Think about how easily a negative review spreads on social media – one bad batch can create a ripple effect you absolutely want to avoid.

Navigating the Complexity of Global Supply Chains

The journey of a souvenir from a China souvenir factory to your warehouse often spans thousands of miles, crosses multiple borders, and involves numerous touchpoints. Each step presents potential risks for quality degradation – from manufacturing inconsistencies to packaging failures during transit. A robust global souvenir supply chain strategy integrates quality checkpoints at every critical juncture, offering full transparency and control. This complex ballet of production and logistics demands an equally sophisticated approach to QA, ensuring every component, every process, and every package meets stringent international compliance standards.

Building an Ironclad QA Framework: Stages, Standards, and Strategic Implementation

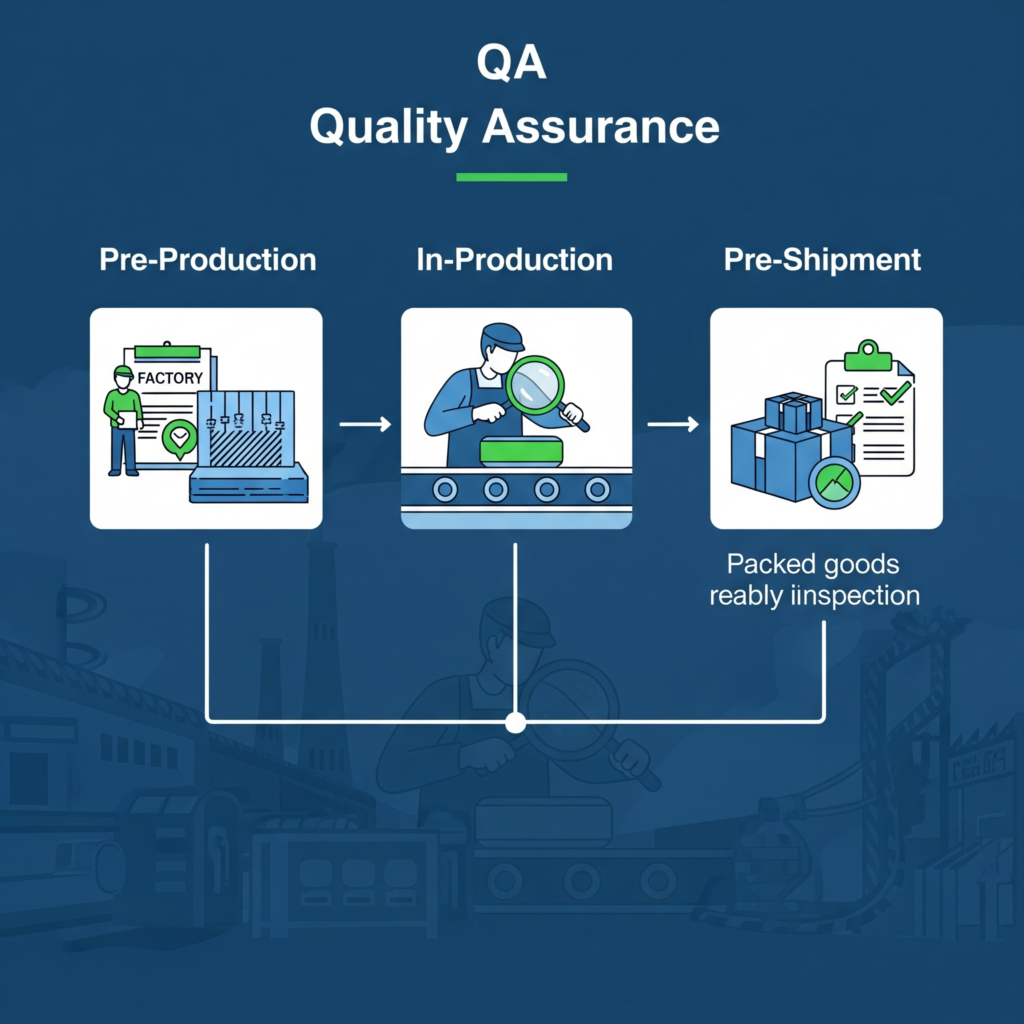

True quality assurance extends far beyond a simple final inspection. It’s a holistic, multi-stage process woven into the very fabric of the manufacturing journey. For bulk souvenir orders, this systematic approach is your best defense against common pitfalls.

Pre-Production: Laying the Foundation for Excellence

Quality assurance truly begins long before manufacturing even starts. This crucial stage involves meticulous planning, validation, and setting the groundwork for defect prevention. It’s here that you solidify the blueprint for your customized souvenirs.

- Supplier Vetting and Factory Audits: Before committing to a souvenir supplier China, conduct thorough factory audits. This isn’t just a checkbox exercise; it’s about assessing their entire operational integrity. Look at their production capabilities, machinery, management systems, and social compliance (important for ethical sourcing). Critically, delve into their existing QA protocols: Do they have dedicated QA staff? What are their internal procedures? A reputable resin souvenir manufacturer or ceramic souvenir factory China should welcome such scrutiny, providing transparency into their operations. This foundational step is paramount for any large-volume buyer.

- Material and Component Inspection (IQC): Incoming Quality Control (IQC) is your first line of defense. This ensures that all raw materials and components – be it the pigment for a resin craft for souvenir, the clay for a ceramic souvenir China, or the wood for a wooden souvenir China – meet your exact specifications before they enter the production line. Catching issues here saves immense rework, waste, and downstream delays. Imagine receiving a batch of off-spec colors for wholesale customized resin souvenir China; identifying this early saves days or even weeks of corrective action.

- Golden Sample Approval & Specification Lock-down: This is your definitive benchmark. A “golden sample” (sometimes called a control sample) is a meticulously crafted pre-production sample that is approved by you, the buyer. It perfectly represents the final product’s desired quality, material, color, finish, and all specifications. Every subsequent unit of your bulk souvenirs must match this standard. Alongside this, lock down detailed product specifications, including dimensions, weight, materials list, color codes (e.g., Pantone), artwork files, and packaging requirements. This eliminates ambiguity and provides a clear target for the China souvenir factory.

In-Production: Vigilance on the Assembly Line

Once production begins, continuous monitoring and swift intervention are vital to catch deviations early and ensure consistency across large wholesale souvenirs batches. This stage is where a proactive souvenir quality control strategy truly shines.

- Initial Production Check (IPC): Performed when approximately 10-20% of the production is complete, an IPC verifies that initial production runs match the golden sample and that any issues identified during pre-production have been effectively addressed. This prevents the large-scale production of defective units, which is a major concern for orders of 1200 PCS and beyond. It’s a cost-effective way to course-correct early.

- During Production Inspection (DPI): Throughout the entire production run, random checks are performed by QA personnel. This helps monitor quality consistency, identify potential issues with machinery calibration, worker training, or process adherence. For instance, if you’re producing iron art souvenir China, a DPI would check welding integrity, finish application, and assembly accuracy at various points. This ongoing vigilance ensures that quality doesn’t dip after the initial good run.

- Process Control and Workmanship Audits: Beyond just inspecting the product, robust QA also evaluates the manufacturing processes themselves. Are standard operating procedures (SOPs) being followed? Are workers adequately trained and following best practices for a resin souvenir manufacturer? Is the workspace clean and organized to prevent contamination or damage? These seemingly minor details directly impact the final product quality and consistency of your bulk souvenir orders.

Pre-Shipment: The Final Gatekeeper Before Global Transit

This is your last, crucial opportunity to verify product quality and quantity before your travel souvenirs leave the factory doors for their journey across borders. This step is indispensable for safeguarding your investment.

- Final Random Inspection (FRI) / Pre-Shipment Inspection (PSI): This is perhaps the most well-known and critical QA stage. Conducted when 80-100% of your wholesale souvenirs order is complete and packed, a PSI comprehensively verifies quantity, product specifications, labeling (including barcodes and country of origin), packaging integrity, and overall product quality against your golden sample and the Acceptable Quality Limits (AQL) you’ve defined. It’s your last line of defense against significant defects reaching your distribution centers.

- Loading Supervision: For particularly large bulk souvenir orders, supervising the container loading process is highly recommended. This ensures that the correct quantity of goods is shipped, that items are loaded properly to prevent shifting and damage during transit, and that the container is securely sealed. This step helps mitigate shipping damage and discrepancies, reducing future headaches related to souvenir import logistics.

International Standards and Certifications

Reputable souvenir suppliers China will often adhere to international quality management standards, offering an additional layer of confidence.

- ISO 9001: This globally recognized standard outlines requirements for a Quality Management System (QMS). A manufacturer with ISO 9001 certification demonstrates a commitment to consistent processes, continuous improvement, and customer satisfaction. While it doesn’t certify the product itself, it certifies the system by which the product is made, which is crucial for bulk buyers.

- Specific Product Certifications & Compliance: Depending on the material, end-use, and destination market, products might require specific certifications. For instance, testing for lead content or phthalates (common for resin craft for souvenir items), CE marking for the European market, or CPSIA compliance for children’s items sold in the US. Understanding and verifying these certifications is a key part of your international compliance strategy and protects you from potential legal issues or recalls.

The Strategic Value: How Robust QA Fuels Your Business Growth

Implementing a rigorous QA process isn’t just about avoiding problems; it’s a proactive investment that delivers tangible, measurable returns for souvenir importers, wholesalers, and brand retailers. It shifts the paradigm from reactive problem-solving to proactive value creation.

Minimizing Financial Losses and Chargebacks

Let’s be brutally honest: every defect costs money. Without proper QA, the financial risks associated with bulk souvenir orders can be staggering, leading to a domino effect of expenses.

*Note: These figures are illustrative and can vary widely based on product complexity, material, specific defects, and freight costs. “Cost of Rework/Returns” includes shipping, labor, potential discounts/refunds, and lost sales opportunities.

As you can clearly see, investing in comprehensive souvenir quality control upfront significantly reduces the risk of substantial financial drains from defective goods, expensive returns, and lost inventory value. It’s a clear case of “pay now or pay much more later.” This direct impact on your bottom line makes robust QA a profit-enhancing strategy.

Safeguarding and Enhancing Your Brand Reputation

Your brand is your most valuable asset in the competitive global souvenir market. When your travel souvenirs consistently meet and even exceed quality expectations, you reinforce that trust with every single sale and every happy customer. Conversely, a single batch of subpar customized resin crafts can quickly lead to scathing online reviews, retailer complaints, and a tarnished image that’s incredibly difficult and costly to repair. Think about a private label souvenir – it carries your name, and therefore, your reputation. Robust QA is a direct and proactive investment in your brand’s longevity, integrity, and market standing. It signals to your customers and partners that you stand behind your products.

Enhancing Customer Satisfaction and Driving Repeat Business

Happy customers are the lifeblood of any business. When tourists buy a souvenir – whether it’s a resin fridge magnet, a beautifully crafted wooden souvenir, or a delicate ceramic souvenir – and find it to be well-made, durable, and exactly as advertised, they’re more likely to cherish it, proudly display it, and crucially, remember your brand or the retailer. This positive experience fosters satisfaction, encourages repeat purchases, and generates valuable word-of-mouth referrals. For wholesale souvenir gifts, this translates directly into repeat orders from your retail clients who are seeing positive feedback from their end-consumers.

Streamlining Supply Chain Efficiency and Reducing Delays

Effective QA isn’t just about finding problems; it’s fundamentally about preventing them. By identifying and rectifying issues early in the production cycle – thanks to IPC and DPI – you avoid costly delays, emergency reworks, and the nightmare of rushed, expensive shipments. This leads to a smoother, more predictable global souvenir supply chain, which is invaluable for bulk buyers operating on tight deadlines and managing complex inventory. A well-managed QA process is a cornerstone of effective supply chain risk management, ensuring your products move efficiently from the China souvenir factory to your distribution network.

Strategic Sourcing: Partnering with QA-Centric Manufacturers

For souvenir importers, wholesalers, and brand retailers, choosing the right manufacturing partner is paramount. You need a souvenir supplier China that doesn’t just talk about quality, but lives it, breathes it, and demonstrates it with every order. Your manufacturer’s commitment to quality is an extension of your own.

Identifying a Truly QA-Focused Manufacturer

When evaluating potential manufacturing partners, delve deep into their QA practices. Don’t just ask if they have QA; ask how they implement it, who is responsible, and what metrics they track.

- Transparency and Communication: A top-tier manufacturer is transparent about their processes and highly responsive to your concerns. They should willingly provide detailed inspection reports, production updates, and proactively communicate any potential challenges or deviations. This open dialogue is crucial for building trust, especially when dealing with large bulk souvenir orders.

- Dedicated QA Teams & Culture: Look for factories with dedicated, well-trained QA teams that operate independently from the production line. This ensures unbiased inspections. A truly quality-focused factory cultivates a culture where every employee understands their role in maintaining standards, from the shop floor to management.

- Certifications and Compliance: While certifications alone don’t guarantee perfection, relevant industry certifications (like ISO 9001 for quality management systems) demonstrate a foundational commitment to standardized quality procedures. Discuss their adherence to international product safety and international compliance standards relevant to your specific souvenir craft types and target markets.

- Experience with Your Specific Product Niche: If you’re primarily importing resin fridge magnets, partnering with a specialized resin fridge magnet manufacturer China will be invaluable. Their deep expertise in that specific material and product type means they’re already familiar with common issues and best practices for quality, significantly reducing your defect prevention efforts. Similarly, if you’re sourcing wooden souvenir China, look for specialists in wood craftsmanship.

The Craft Manufacturer China Advantage: A Commitment to Excellence

At Craft Manufacturer China, our quality assurance protocols are deeply embedded in every stage of our production process, from initial design consultation to final packaging. We understand the unique demands of bulk souvenir orders for international clients like souvenir importers, wholesalers, and brand retailers who require MOQ 1200 PCS and beyond.

- Rigorous Material Sourcing and IQC: We meticulously vet all raw material suppliers, conducting thorough Incoming Quality Control (IQC) checks. This ensures that only the highest quality inputs are used for your customized souvenirs, whether it’s the resin for intricate figurines or the pigments for vibrant designs. This proactive step prevents quality issues from the very beginning.

- Multi-Stage Inspection Protocol: Our dedicated QA team implements a comprehensive, multi-layered inspection approach. This includes initial production checks, in-process inspections throughout the manufacturing cycle, and a stringent final pre-shipment inspection. This meticulous approach ensures consistent quality across all wholesale customized resin souvenir China orders, as well as ceramic souvenir factory China products or iron art souvenir China items. We verify every detail against your approved golden sample.

- Customization and Adherence to Standards: We thrive on customization. Our processes are highly adaptable to your specific quality requirements and precise branding guidelines for private label souvenirs. We work closely with you to define Acceptable Quality Limits (AQLs) that align with your market’s expectations, ensuring every single unit meets your exact specifications for souvenir product development.

- Transparency and Open Communication: We believe in fostering long-term partnerships built on trust. We maintain open communication channels, providing you with detailed inspection reports, production progress updates, and swift responses to any queries. This transparency gives you complete peace of mind, knowing your travel souvenirs are in expert hands from order placement to delivery.

- Ethical Sourcing and Compliance: Beyond product quality, we adhere to ethical sourcing practices and ensure compliance with relevant international labor and environmental standards. This commitment adds another layer of assurance, especially for brand retailers who prioritize responsible supply chains.

Conclusion: Elevating Your Brand Through Uncompromised Quality

In the ever-expanding global souvenir market, quality assurance is no longer a peripheral concern; it’s a core competitive differentiator. For souvenir importers, wholesalers, and brand retailers navigating bulk souvenir orders, a robust QA framework isn’t just a protective measure – it’s the ultimate shield against risks and the most powerful driver of long-term success.

By understanding the critical stages of quality control, strategically partnering with a China souvenir factory that prioritizes excellence, and leveraging advanced QA practices, you can confidently bring superior travel souvenirs to market. This unwavering commitment to quality will not only safeguard your profits and minimize potential losses but also elevate your brand’s reputation, fostering enduring customer loyalty and ensuring your position at the forefront of the industry. Don’t just import souvenirs; import confidence.

Frequently Asked Questions (FAQs)

- Q1: Why is quality assurance so crucial for bulk souvenir orders exceeding 1200 PCS?

- A: For bulk souvenir orders of this size, even a small percentage of defects can lead to significant financial losses from wasted goods, costly reworks, and logistical nightmares. Robust souvenir quality control minimizes these risks and ensures consistency across thousands of units, directly impacting your profitability and reputation when dealing with souvenir suppliers China.

- Q2: What are the key stages of a comprehensive QA process for international souvenir manufacturing?

- A: A comprehensive QA process covers the entire product lifecycle: pre-production (supplier vetting, IQC, golden sample), in-production monitoring (IPC, DPI, process audits), and pre-shipment inspections (FRI/PSI, loading supervision). This holistic approach is vital for an effective global souvenir supply chain.

- Q3: How can I ensure the quality of my customized resin crafts when ordering in large volumes from overseas?

- A: When sourcing customized resin crafts in bulk, ensure your resin souvenir manufacturer implements strict quality checks for material consistency, mold accuracy, color matching, and final finish. Always request pre-production samples and detailed inspection reports to ensure defect prevention.

- Q4: What should souvenir importers look for in a China souvenir factory that truly prioritizes quality assurance?

- A: Look for transparency in their processes, dedicated and independent QA teams, relevant certifications (like ISO 9001), and a willingness to facilitate third-party inspections. Their experience with wholesale souvenirs and adherence to international compliance standards are also critical indicators.

- Q5: Beyond just preventing defects, how can strong QA benefit my brand as a brand retailer dealing with private label souvenirs?

- A: Robust QA directly safeguards your brand reputation, building customer trust and encouraging repeat business by consistently delivering high-quality products. For private label souvenirs, your brand name is on the line, making uncompromising quality a powerful differentiator and a key part of your supply chain risk management strategy.

- Q6: What’s the typical lead time for comprehensive QA processes on large wholesale customized resin souvenir China orders?

- A: While the QA process is integrated, it’s crucial to factor in time for pre-production sample approvals (which can take 1-2 weeks), and subsequent inspection windows. A dedicated resin souvenir manufacturer will typically have these timelines built into their production schedule.

- Q7: How does Craft Manufacturer China address souvenir quality control for different materials like wood and ceramic?

- A: At Craft Manufacturer China, our QA protocols are tailored to each material. For wooden souvenir China, we focus on wood integrity, carving precision, and finish durability. For ceramic souvenir China products, we prioritize glaze consistency, firing quality, and structural integrity to minimize breakage. Our multi-stage inspection applies across all materials.

- Navigating the Currency Storm: De-Dollarization and Souvenir Pricing in 2025/2026 - March 4, 2026

- Navigating the 139th Canton Fair Phase 2: Tips for Efficient Sourcing of Gifts and Souvenirs - February 26, 2026

- Resin vs. Ceramic: A Data-Driven B2B Comparison for High-Volume Souvenir Orders - February 4, 2026